A crevice is a narrow gap between a piece of metal and another piece of metal or tightly adhering material like plastic or a film of bacterial growth.

Many metals and alloys are susceptible to crevice corrosion, but in stainless steel, crevices are the first and most common place for corrosive attack to begin. With a little understanding, crevice corrosion can either be avoided or minimised.

Crevices can be:

• The space under a washer or bolt head.

• The gap between plates bolted together.

• The gap between components intermittently welded.

• The space under a sticky label.

• The space between a gasket and the metal in a flange (especially if the gasket is absorbent).

• Any other tight gap.

Crevices can be designed into the structure, they can be created during fabrication or can occur during service.

Prevention measures should therefore also aim at design, fabrication and service.

Why crevices can corrode

To work at its best, stainless needs free access to oxygen. Crevices are wide enough to permit entry of moisture, but narrow enough to prevent free circulation.

The result is that the oxygen in the moisture is used up. In addition, if chlorides are present they will concentrate in the stagnant conditions and, by a combination of reactions, the moisture can become acidic.

These are all conditions that can lead to the breakdown of the passive film on the stainless. Attack can then progress rapidly.

Crevices can create conditions much more aggressive than on adjacent surfaces. Having crevices builds in weak spots where attack can begin and begin in much less severe conditions than anticipated for the remainder of the structure.

Table one shows laboratory measurements of critical temperatures needed to cause pitting on an open surface (CPT) and crevice (CCT) attack of a metal plate beneath a PTFE washer in a 10% ferric chloride solution.

The CCT is at least 20˚C lower than the temperature to cause pitting corrosion in this aggressive liquid. (Ferric chloride solution is an aggressive corrodent and is used because it is similar to the liquid in a pit when it is actively corroding.)

Factors influencing crevices:

Crevice Shape

The geometry of the crevice will influence its susceptibility to attack and the speed of progress. The narrower and deeper (relative to its width) a crevice is the worse attack will be.

Metal to flexible plastic crevices tend to be narrower than rigid metal to metal gaps so metal to plastic joints provide more aggressive crevices.

Environment

The more aggressive the liquid outside the crevice, the more likely it is that the crevice will be attacked.

This is why crevice attack can be a problem in a salty swimming pool but not in a fresh water tank.

In the atmosphere, crevices beside the sea give more problems than in rural environments. If the liquid outside the crevice is very oxidising, eg with bleach, hydrogen peroxide or ozone, then crevice attack will tend to be more severe.

Temperature

Once the CCT is exceeded, then as with pitting corrosion, higher temperatures mean corrosion is more rapid. The rule of thumb is that a 10˚C rise in temperature will double the corrosion rate.

This means that when comparing Far North Queensland to Tasmania, not only are crevices more likely to start corroding but also that once they do, they will corrode faster because the temperature is consistently higher.

Alloy resistance

Using a more corrosion resistant alloy gives less crevice attack. For example, in seawater at ambient temperature, crevices will form on 304 if there is a 0.9mm gap, on 316 if there is a 0.4mm gap and on 904L (similar corrosion resistance to 2205) if there is a 0.15mm gap.

Minimising the risk of crevice corrosion

Good design, fabrication and operating practices will anticipate and hence minimise crevice corrosion.

Design

Design to minimise the occurrence of crevices. If a crevice is a necessary part of a component’s design – can it be made wider?

Full penetration butt welds are best for joints. Seal lap joints and avoid gaps between pipes and fittings.

Minimise use of bolted connections and other fasteners. Where crevices can’t be avoided use a steel grade resistant to crevice corrosion in the operating environment. It is also possible to seal the crevices to keep out corrosive liquids, but care must be taken that the seal is permanent.

Be careful that the sealant “wets” the surface. If it doesn’t it may form its own crevice. Sealants that dry and shrink can form their own crevices.

Gaskets between flanges will probably form a slight crevice, but if the gasket does not absorb the liquid and is compressed between the surfaces (and not bulging around the flange), then the crevice is usually shallow enough so that crevice corrosion is not a problem.

Fabrication

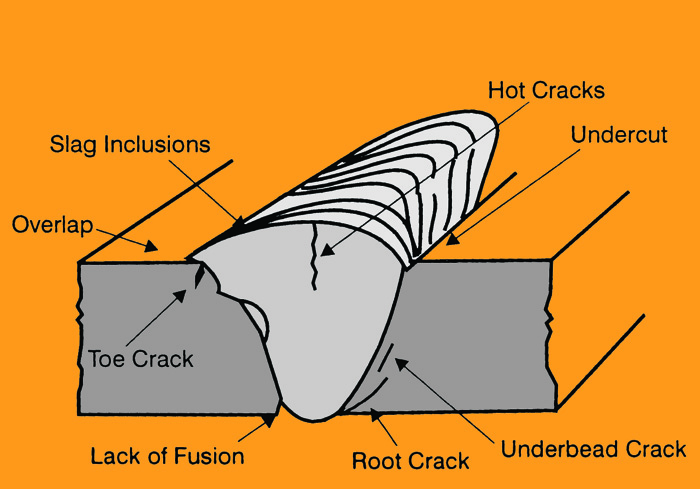

Ensure full root penetration of welded joints with smooth weld bead. Avoid under cut and cracks in welding. Use of sticky labels or markers of various kinds (such as crayons) should be avoided, as should smears of grease or oil.

“Smooth and clean” at all times. ASSDA Accredited Fabricators are assessed on their knowledge of crevice corrosion.

Operation

Sediment and scale can both result in crevices.

If the problem can’t be designed out, routine maintenance will minimise risk. Crevice corrosion under bacteria film can occur. Maintaining circulation reduces the risk that debris will collect and form crevices in dead legs or low flow areas.

Further Reading

The Nickel Institute’s free publication #11021 “High Performance Stainless Steels” contains much of the information used in this article.

This publication and a mathematical model useful for assessing crevice corrosion risk can be downloaded from the Nickel Institute website - www.nickelinstitute.org

If more detailed corrosion mechanism information is required, then “Corrosion of Stainless Steels” by A. John Sedriks is a good intermediate point.

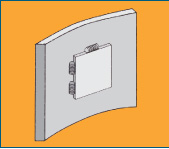

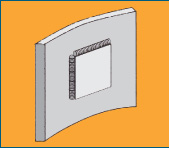

Reinforcing pad, staggered welds - adequate strength.

Reinforced pad, seal weld - best corrosion resistance.

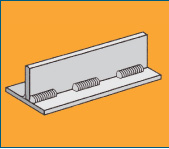

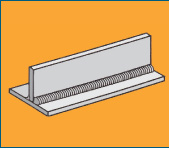

Staggered fillets - severe crevice

Continuous fillets both sides - crevice sealed

Figure 1: Typical crack defects around a weld (WTIA)

Credits

The Australian Stainless Steel Development Association (ASSDA) would like to acknowledge the contribution of the following Technical Committee members for their contribution to the production of this article.

• Richard Matheson - Executive Director, ASSDA

• Graham Sussex - Technical Specialist, ASSDA

• Peter Moore - Technical Services Manager, Atlas Specialty Metals

This article featured in Australian Stainless magazine - Issue 29, January 2004.