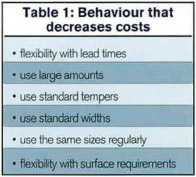

Stainless steels are now cheaper than ever, but there is still room to minimise costs (see Table 1), which will improve the bottom line for individual companies, projects and the industry as a whole.

Australia is a relatively 'small fish' in the global stainless industry and, without the benefit of local stainless steel production, loses some flexibility on product availability. Unless you're a very large consumer of stainless steel to a single specification or Standard, ordering to common specifications will reduce costs and increase availability of products.

Australia is a relatively 'small fish' in the global stainless industry and, without the benefit of local stainless steel production, loses some flexibility on product availability. Unless you're a very large consumer of stainless steel to a single specification or Standard, ordering to common specifications will reduce costs and increase availability of products.

Suppliers are likely to have products to common specifications. Ordering them reduces the need for slow moving stock, increases stock turns, raises the size of single orders, and can substantially reduce costs. A similar mechanism works for mill or mill indent orders.

Suppliers are likely to have products to common specifications. Ordering them reduces the need for slow moving stock, increases stock turns, raises the size of single orders, and can substantially reduce costs. A similar mechanism works for mill or mill indent orders.

Flat products

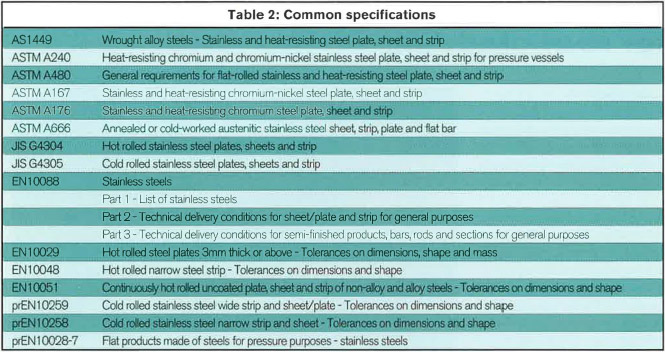

Until recently, stainless steel flat products manufactured to Australian Standard 1449 were the most widely available in Australia. However, since the closure of BHP Stainless in 1997, products manufactured to this Standard are no longer commonly produced. More common international specifications will need to be recognised in Australia if economies are to be achieved (see Table 2).

Fortunately, the transition may not be difficult, because AS1449 was closely aligned with the ASTM Standards from the USA, which are also similar to the Japanese JIS Standards. Steels identical to AS1449 in nomenclature, chemical composition, mechanical properties and surface finish are readily available internationally.

Today the most commonly available stainless flat product in Australia is manufactured abroad to ASTM A2401A240M Standard specification for heat resisting chromium and chromium-nickel stainless steel plate, sheet and strip for pressure vessels, which nominates ASTM A4801A480M for additional general requirements of the steel ('M' designates the metric version, which is more appropriate in Australia).

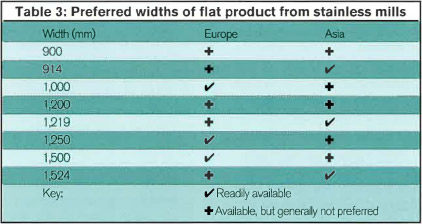

European specifications are also emerging and EN 10088 Stainless steels has the potential to become a common specification in the Australian market. EN 10088 makes use of the established German names and numbers for stainless steel grades, Many grades in EN 10088 have close equivalents in the ASTM based Standards, but the nomenclature for grades and finishes is very different and replacements should be examined carefully. For example, in AS1449, ASTM A240M and JIS G4305, grade 304 (the most common stainless) has a minimum of European specifications are also emerging and EN 10088 Stainless steels has the potential to become a common specification in the Australian market. EN 10088 makes use of the established German names and numbers for stainless steel grades. Many grades in EN 10088 have close equivalents in the ASTM based Standards, but the nomenclature for grades and finishes is very different and replacements should be examined carefully. For example, in AS1449, ASTM A240M and JIS G4305, grade 304 (the most common stainless) has a minimum of Ordering at standard width and thickness is the best way to keep steel costs down. Each mill has equipment capable of a certain maximum width and running narrower steel is less productive.

The standard width varies from mill to mill (see Table 3), with most European mills manufacturing at 1,200mm or 1,250mm wide, with a few capable of 1,500mm and, for some thicker coil products, 2,000mm. Mills in Asia tend to standardise on the imperial widths 3', 4' and 5' (914mm, 1,219mm, 1,524mm).

Conclusions

An understanding of commonly used specifications can lead to more efficient and cheaper practices. If questions arise, your supplier or fabricator may have information on alternative Standards that are more commonly available and more suited to your requirements.

This article featured in Australian Stainless Issue 11 - March 1998. More current information can be found in ASSDA's Australian Stainless Reference Manual.