The overwhelming response from the architecture community to our earlier article on precision folding of stainless steel sheet using vee-cutting technology has prompted a more in-depth look at the process.

Thanks to vee-cut technology, stainless steel sheet can be formed into angles as precise as those obtained by extrusion. This technology is now being carried out in Sydney, allowing the local manufacture of a whole range of stainless steel architectural products. The technique is particularly suited to elements such as door fronts, window frames, shopfronts, showcases, elevator doors as well as all forms of cladding.

Thanks to vee-cut technology, stainless steel sheet can be formed into angles as precise as those obtained by extrusion. This technology is now being carried out in Sydney, allowing the local manufacture of a whole range of stainless steel architectural products. The technique is particularly suited to elements such as door fronts, window frames, shopfronts, showcases, elevator doors as well as all forms of cladding.

In a completely new method of manufacture, vee-cutting can also be used to make flat products such as tread plates for lifts and escalators by removing strips of material to the required width and depth.

CLEAN LINES COMPLEMENT SPECIAL FINISHES

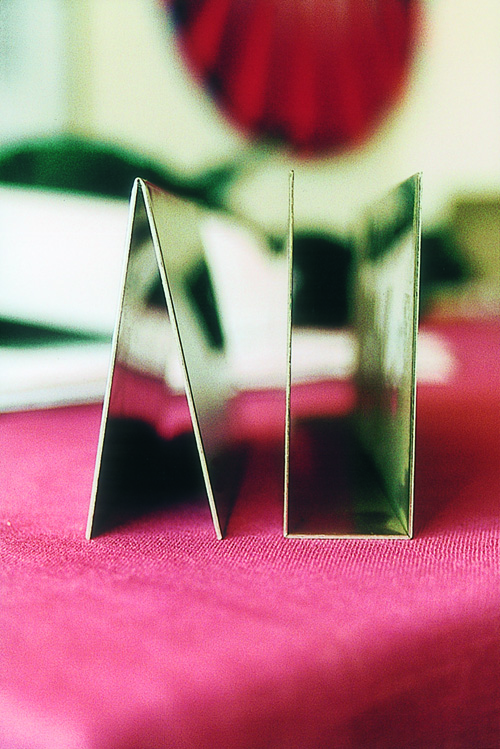

Ordinary bends made on a brake press typically produce a corner radius twice the thickness of the sheet, resulting in a finished product with soft, blurred lines. But with the introduction to Australia of vee-cut technology, it is now possible to produce stainless steel with corners as precise as an extruded angle, such as those found on aluminium window frames.

The method is particularly useful when working with textured and patterned stainless sheet. Such finishes are distorted by the traditional bending method. Using the vee-cut machine, the feature finish is preserved without loss of quality. This makes it the manufacturing method of choice for items such as bar fronts, display cases, door furnishings and a myriad of other uses where appearance counts.

THE VEE-CUTTING PROCESS

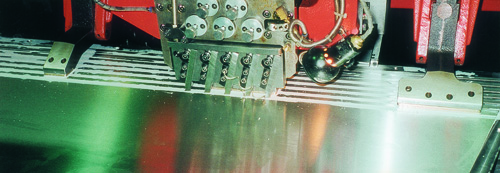

The machine cuts a continuous vee-shaped notch in the sheet using a series of five tools, which make repeated passes across the surface. The number of passes required varies depending on the thickness of the metal; generally three or four are needed, but up to 15 can be required for thicker product.

The machine can handle thicknesses in the range of 0.6mm to 6.0mm and is capable of cutting to a minimum depth of 0.4mm and processing sheet up to 4m in length. The sheet is then folded along the groove in a brake press. The depth of the groove can be set for acute angles down to 15°.

When used for cladding, up to 70% of the thickness of the sheet can be removed; however, care needs to be taken not to weaken structural components by removing too much of the thickness. One option is to remove material to obtain a tight corner and then stitch weld to restore strength – it is a matter of weighing up cost and other considerations.

A TYPICAL APPLICATION - ENTRANCE DOORS

A TYPICAL APPLICATION - ENTRANCE DOORS

An example of the finish available can be seen in the revolving doors of the McKell Building in Sydney (pictured). Byrnes Entrance Technology Pty Ltd (BET) worked with ASSDA member the Townsend Group to produce profiles and folded panel sections to clad the central steel and aluminium core of the triple door. The final effect is the appearance of a solid, triangular-shaped central column with lightly inward-curving sides.

This article featured in Australian Stainless magazine - Issue 22, September 2002.