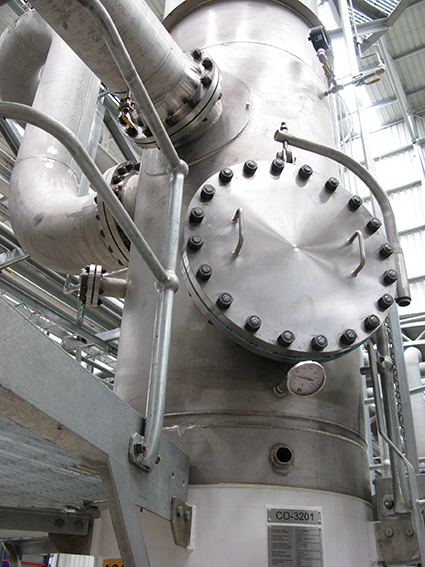

Seven pressure vessels and five columns were fabricated by ASSDA Accredited D&R Stainless from 30 tonnes of grade 304 stainless

steel supplied by ASSDA member Sandvik.

The column sizes range from an acid reduction column 750mm in diameter and 14.2 metres long to a beer column 1900mm in diameter and 24 metres long.

The columns were fabricated to tight tolerances set by process design engineers Detla T Technology, in the United States.

Chief Executive Officer of Dalby Bio-Refinery Limited, Kevin Endres, has worked with Delta T technnology in the US.

Mr Endres said stainless was the obvious choice for its durability. A project of this size requires a low maintenance and reliable material.

All design and manufacturing was carried out by D&R Stainless to ASME VIII complying with AS1210.

D&R also fabricated 6000 metres of grade 304 piping in sizes from 20NB to 500NB requiring over 6100 elbows, flanges and fittings from ASSDA member Stainless Pipe & Fittings Australia.

All piping was x-ray quality and met ASME B31.3.

Mr Endres said the refinery will eventually expand to output over 200 million litres of ethanol per year.

This article appeared in Australian Stainless Magazine - Issue 45, Summer 2009.