Posted 31 July 1993

Life Cycle Costing (LCC) has long been used in planning for reliability and maintenance for complex engineering systems in defence, airline, railway, offshore platform, power station, and other applications.

A basic attribute of stainless steel is the ability to provide long-term perfor-mance with a minimum of downtime and cost associated with maintenance. As a result LCC is of particular importance to the stainless industry.

Whilst the mathematics of LCC can be quite complex the International Chromium Development Association (ICDA) has developed an IBM or compati-ble PC program on floppy disk which can be easily applied to most examples.

The Australian Stainless Steel Development Association can make this program available to any interested party on request.

LCC analysis provides a more secure basis for comparing and selecting material options than the traditional method of judgements based on comparing acquisition costs alone. This particularly applies to situations where the initial cost is high and downtime for unplanned maintenance is costly.

In circumstances where stainless is being considered or introduced into new fields of applications, comparisons are often made with materials of a lower initial cost such as coated carbon steel or plastics.

Here the reasoning should progress well beyond the simple initial cost com-parison and take account of the long term cost assessments associated with mainte-nance replacement and operating stop-pages.

LCC is the tool to make this assessment and the ICDA program makes it easy.

Calculating LCC

In the LCC calculation, consideration is given only to relevant costs which are directly or indirectly affected by the material options being considered. Besides the cost of material, these include costs of installation, operation, maintenance, stop-pages, replacements and possibly the residual value at the end of the service life. The time intervals at which the various costs arise during the selected life cycle period must also be taken into account.

Before the various cost items can be put together, those that arise every year and those that occur at certain time intervals during the service life must be converted into present values.

Again the complexities of the mathematics are catered for by the PC program.

Examples are the best way of demonstrating LCC principles and application and two are offered to illustrate the point.

The first is from Swedish practice and features roofing.

The building industry is one of the most rapidly expanding markets for stainless steel and roofing is a major growth application. A method based on seam welding 0.4mrn strips of cold rolled stainless steel was invented in Sweden in the 60's and has since found favour in Europe and Japan. An LCC calculation was carried out based on these material options:

• galvanised and plastic coated carbon steel, double folded edges

• 0.4mm stainless stee I strip, seam-welded and single folded edges (type 316 for coastal areas or polluted atmospheres, otherwise type 304).

In this example the LCC period is 50 years and a real interest rate of 3% is used (comparative figures are given per sq metre):

| Material | Material Cost | Installed Cost | LCC |

| Carbon steel | 1.1 | 2.1 | 2.1 |

| Stainless Steel type 316 | 2.0 | 2.8 | 1.4 |

| Stainless Steel type 304 | 1.6 | 2.6 | 1.3 |

The LCC result shows that stain-less steels are less costly than galvanised and plastic coated steel. Galvanised carbon steel requires replacement after about 20 years. The calculation does, however, not take into account the risk of damage to building substructures each time the covering is replaced. The stainless steel alternative is the only one which is virtually maintenance free.

The second example is a mixing tank for a water treatment plant.

The dimensions of the tank are 3 metres long, 1.5 metres wide and 1.5 metres high. The entire tank is raised off the floor by four steel channels beneath the tank; these ensure that spills do not accumulate beneath the tank.

The design brief requested evalua-ion of three materials. (i) mild steel with applied fibre-glass lining, (ii) stainless steel alternatives of Type 304 and duplex grade 2205 (UNS S31803).

As the 2205 was not readily avail-able in angle and channel products, these were substituted by type 304 for the 2205 design as these components were not to be in regular contact with the corrosive environment.

The evaluation was carried out using the LCC PC program from the International Chromium Development Association available in Australia through ASSDA.

Experience suggested that both the 304 and 2205 would probably survive without replacement for the full twenty years, whereas the mild steel was expected to last for only about eight years before replacement. In addition both the stainless steels were expected to require only minimal inspection and cleaning as regular maintenance in comparison with fairly extensive patching of the mild steel and its lining.

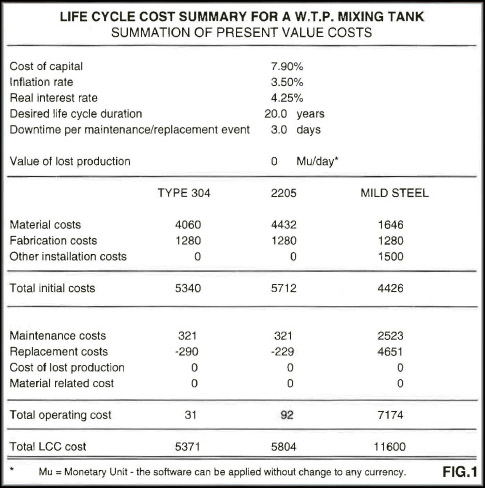

The "Summary of Present Value Costs" table of Figure I shows the resulting LCC analysis -the Type 304 stainless steel is lowest cost, closely followed by the 2205 and with mild steel substantially more expensive due to its higher maintenance and replacement costs.

The "Value of Lost Production" in the summary table is shown as zero -this implies all maintenance and replacement is carried out in scheduled shut downs for other plant maintenance. Shut downs causing lost production could substantially add to the Total Operating Cost of the option requiring this unscheduled maintenance.

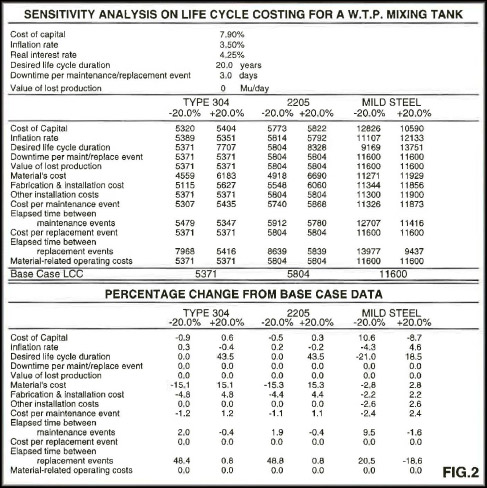

The ICDA LCC software also gives a more detailed breakdown of the contributions to the initial costs and operating costs, and a "sensitivity analysis" on all the inputs which is shown in Figure 2. The latter gives the effect on the total LCC for each material option of an independent change (eg of 20%) in each of the inputs. This information is vital in determining which of the input items must be accurately known and which are of lesser importance. In this case the sensitivity analysis indicates that the most critical data is the time before replacement becomes necessary. The assumption was that the 304 and 2205 would both survive for the full twenty years; from the sensitivity analysis it is apparent that if the 304 fails before this time (possibly due to its lower pitting corrosion resistance compared to the 2205), the 2205 duplex stainless steel becomes by far the cheaper option. Clearly a good knowledge of the actual operating conditions to be encountered is crucial to the correct selection.

Acknowledgments:

1. This article has drawn on material contained in a publication Life Cycle Costing - Evaluation of a Method of Use For Stainless Steel Applications by Sten Von Matern of Avesta AB, Sweden.

This has been made available to ASSDA through A vesta Sheffield Pty Ltd. This contribution is gratefully acknowledged.

2. The computer diskette "Life Cycle Costing" was developed by and supplied to ASSDA by the International Chromium Development Association.

This article featured in Australian Stainless Magazine - Issue 1, July 1993.