FAQ 9: Welding Dissimilar Metals

Welding the common austenitic stainless steels such as 304 and 316 to each other or themselves is routine and the easiest of fusion welding.

Nevertheless, there are many situations where it is necessary to weld stainless steel to carbon steel. Two common examples are balustrade posts attached to structural steel or doubler plates connecting supports to stainless steel vessels. There are differences in physical properties such as thermal conductivity and expansion, magnetic properties, metallurgical structure and corrosion resistance, which all require attention. This FAQ outlines the necessary procedures for satisfactory welding, including reference to standards, and explains the necessary precautions. Appendix H of AS/NZS 1554.6 has a more detailed technical discussion including advice on welding carbon steel to ferritic, duplex and martensitic stainless steels.

Download ASSDA Technical FAQ 9 (PDF)

WELDING PROCESS

The normal TIG and MIG welding processes are suitable for welding austenitics to carbon steel. As a guide, welding should be carried out at ambient temperature with no pre-heating required (except possibly for drying), unless the carbon steel has more than 0.2% carbon or a thickness of more than 30 mm and giving high restraint, in which case a preheat of 150 °C is usually adequate. Because carbon steels are susceptible to hydrogen cracking, the consumables and the weld area must be dry.

WELD AREA PREPARATION

When welding galvanised steel (or steel coated with a zinc-rich coating) to stainless steel, it is essential to remove the zinc from the heated zone because it is possible to get zinc into the weld, which will cause liquid embrittlement and cracking along the zinc penetration line. It is possible that fume from the zinc coating will cause Occupational Health and Safety (OHS) problems. The weld areas of stainless steel must also be clean and free from grease or oil, as the contaminants will cause carbon pickup and possible sensitisation, leading to intergranular corrosion.

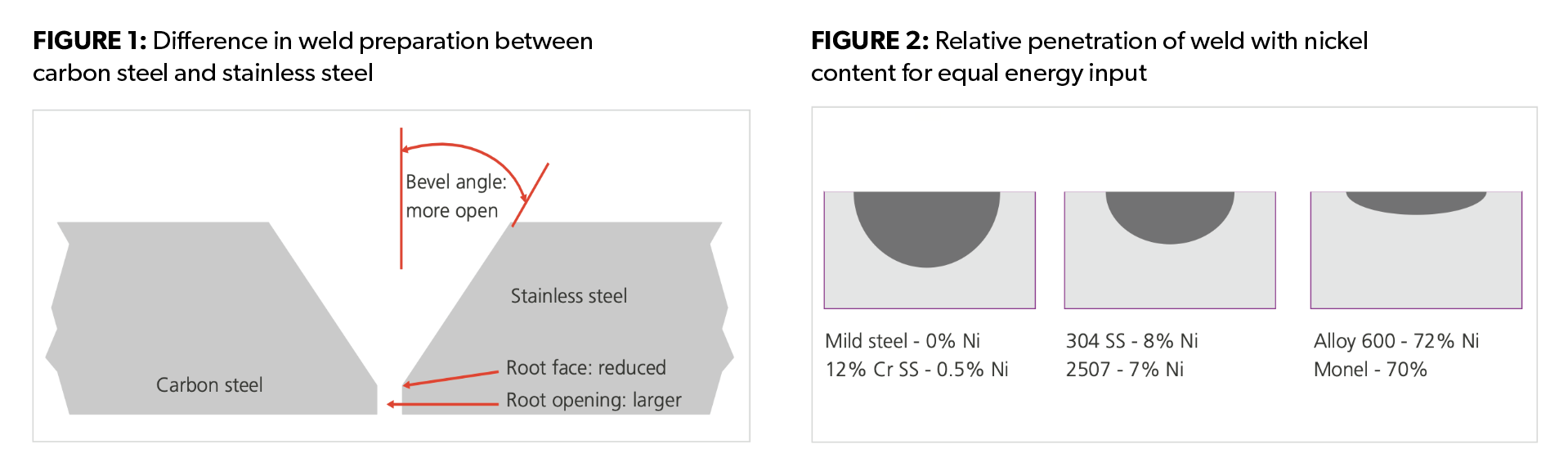

In addition, because the nickel content of the austenitics makes the weld pool more viscous, the weld preparation must be more open (see Figure 1) and the root gap larger to allow wetting. Consumables with added silicon (Si) also assist with edge wetting. An additional effect of the nickel content is that the penetration into the no-nickel carbon steel will be greater than into an austenitic stainless steel (see Figure 2).

WELDING CONSUMABLES (FILLER METAL AND GASES)

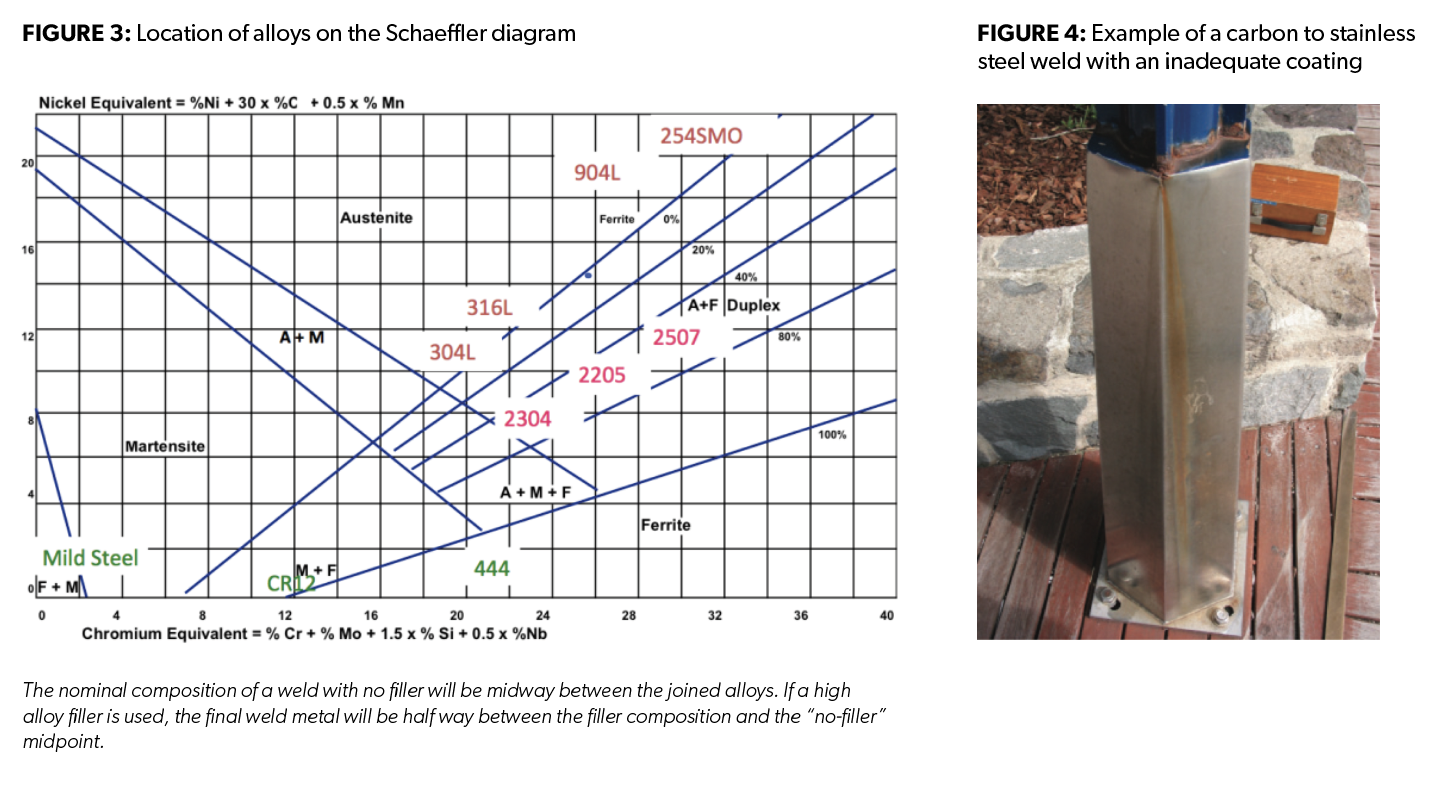

Carbon steel must not be welded directly to austenitic stainless steels as the solidified weld metal will form martensite, which has low ductility and which, as it contracts, is likely to crack. There is an easy way to select the higher alloy filler, which will dilute to give the correct austenitic microstructure with enough ferrite to avoid shrinkage cracks. Refer to Table 4.6.1 in AS/NZS 1554.6. Another way is to use a Schaeffler deLong diagram (see Figure 3) or the WRC 1992 diagram as described in Appendix H2 of AS/NZS 1554.6. The standard recommends that carbon steel to 304(L) uses 309L, and carbon steel to 316(L) uses 309LMo.

If nitrogen additions are used, care is required as it will decrease the ferrite content of the weld metal, which may cause hot cracking.

The shielding gas must not include the oxygen often used in carbon steel mixtures. If an active gas is desired, then low levels of CO2 can be used.

THERMAL EXPANSION

There is a degree of distortion inherent in welding a low thermal expansion carbon steel to a high thermal expansion austenitic stainless steel. The expansion coefficient for mild steel is approximately 12 compared to 17 μm/m/°C for stainless steel in range 0 – 300 °C. There is also the difference between the good heat conduction of the carbon steel compared to the poor heat conduction of the stainless steel (49 to 15 W/m°K at 200 °C respectively), which means that the stainless steel will cool (and contract) more slowly than the carbon steel, especially if the welded sections are thick.

To control distortion, the heat input should be minimised and the joint tacked before making the full weld run. One trick is to tack the ends, centre, 1/4 points and possibly 1/8 points in that order. Heat input and interpass temperature recommendations for stainless steel welding are given in section 5.10 of AS/NZS 1554.6.

POST WELD CLEANING

After welding, clean the weld area to remove slag and heat tint to examine the weld integrity and also to allow the metal to be painted. If possible, blast the weld area with iron free grit but if that is not possible, grind along the weld line to avoid dragging carbon steel contamination onto the stainless steel. ASTM A380 has recommendations for passivation solutions for mixed mild and stainless steel welds. The formulations include peracetic acid and EDTA (ethylenediaminetetraacetic acid), but mechanical cleaning alone is the most common method.

CORROSION PROTECTION

It is assumed that the carbon steel will be painted for corrosion protection. When a barrier or insulating coating is used for painting the carbon steel, carry the paint onto the stainless for up to 50 mm (depending on the environment’s corrosivity) to cover the stainless steel that has been heat affected. Figure 4 shows a carbon-to-stainless steel weld with an inadequate coating. Normally in a stainless-to-stainless weld, the welded fabrication would be acid-pickled and passivated using a hydrofluoric/nitric acid mixture, but this is clearly not possible for a carbon steel to stainless steel fabrication because of the corrosive effect on the carbon steel. If the weld zone is to be exposed to corrosive conditions, and it is intended to use a zinc-rich final coating on the carbon steel, a stripe coating of a suitable barrier paint is required along the edge of the zinc coating to avoid possible galvanic dissolution of the zinc coating adjacent to the stainless steel.

STAINLESS CLEAN UP

Quite apart from any weld to carbon steel, the stainless steel away from the weld area must be protected from contamination during fabrication. This includes weld spatter, carbon steel grinding debris and smearing of carbon steel on the stainless caused by sliding contact between carbon and stainless steels. If contamination occurs, then it must be removed either by mechanical means, followed by use of a nitric acid passivation paste or by the use of pickling and passivation paste. Passivation paste will not affect the surface finish of the stainless steel, whilst pickling and passivation paste will etch the stainless steel. All acids must be neutralised and disposed of according to local regulations. The surfaces must also be thoroughly rinsed after the acid processes.

FURTHER READING

- Nickel Institute Publication No. 14018, Guidelines for Welding Dissimilar Metals.

- Nickel Institute Publication No. 11007, Guidelines for the Welded Fabrication of Nickel-Containing Stainless Steels for Corrosion Resistant Services.

- International Molybdenum Association (IMOA)/Nickel Institute, Practical Guidelines for the Fabrication of Duplex Stainless Steels (3rd edition).

- International Stainless Steel Forum (ISSF), The Ferritic Solution (page 36) deals generally with welding ferritic stainless steels.

- AS/NZS 1554.6:2012 Structural steel welding - Part 6: Welding stainless steels for structural purposes.

- Herbst, Noel F., Dissimilar Metal Welding © Peritech Pty Ltd 2002 (available for download from here).