FAQ 12: Coloured and Patterned Stainless Steel

Think stainless steel, and most people think ‘bright, shiny and silver’. But did you know that specifying stainless steel is not limited by its silver appearance?

Download ASSDA Technical FAQ 12 (PDF)

Coloured and textured stainless steel is an exciting material choice for designers and architects. In addition to offering a high quality and aesthetically-pleasing finish with choice of colour, stainless steel’s superior benefits when compared with plastics or anodised aluminium include resistance to heat, light, abrasion and corrosion, and overall increased durability and performance extending the service life of the application.

This FAQ will take a look back at the development of coloured stainless steel, detail the electrochemical colouring and PVD coating processes, and explore the various surface textures available.

HISTORY AND DEVELOPMENT

Back in the late 1960s, INOX developed a process for uniformly colouring smooth stainless surfaces. The colour relied on the growth of a uniform oxide-based film in a sulphuric and chromic acid mixture. The colour changed because of the interference of reflections from the top of the layer and the metal underneath it. It is like the colours in a soap bubble or an oil film, except that the INOX film had a very uniform thickness. This is because it is grown under uniform temperature and flow conditions with tightly controlled chemistry. Because the colours were subtractive rather than additive, they were not the same as a rainbow spectrum, but colours ranged through bronze, blue, black, charcoal/grey, gold, purple and green as the film grew from 20nm to 360nm. The colours also varied slightly with the viewing angle because of the interference process that gives the colour.

Initially, there were two limitations and two caveats. Firstly, the coatings were easily abraded so it should not be used in heavily trafficked areas because any mechanical damage could not be repaired. Secondly, it was initially only grown on 304. And the caveats? The tight thickness limits mean that batch-to-batch colours could have slight tint variations although, this also has been exploited to provide a softer colour image.

ELECTROCHEMICAL COLOURING

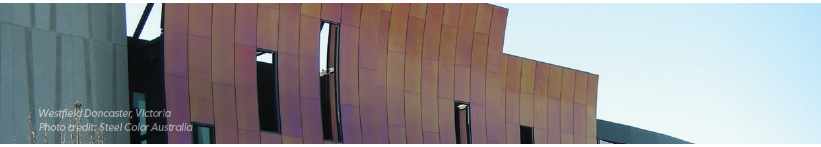

Within a decade, a dual-stage process was developed with an electrochemical treatment that provided greater abrasion resistance. Research in Australia showed that, for 304 base material, the film provided a slight improvement in corrosion resistance although the change is not as significant as a passivation process. Further developments showed that coloured films could also be formed on 316. The necessity for a uniform film thickness still requires factory treatment which means that it is limited to sheets or round surfaces such as tubes. Nevertheless, building facades, shopping centres and smooth surfaced artworks were able to display a variety of stainless steel colours, even when the coloured stainless steel has been carefully bent into shapes.

These colours are very durable, even in Australia, as they do not fade with UV exposure and, in a graffiti-infected urban environment, solvents can be used to remove tags and other unwanted additions to coloured facades and signs. However, they are not repairable if scratched and can only be mechanically fixed as welding locally destroys the coloured film.

SURFACE BLACKENING

Do the arms of your black windscreen wipers use this colouring process? Well, no. The rich, glossy black used to be from immersion of stainless steel in molten sodium/potassium dichromate at 400oC for about 30 minutes but is now usually replaced by a 180oC cured organic coating. Shorter immersion times were used for thermal solar water heaters but they are now either painted or plastic - although black chrome has had a place in the market.

PHYSICAL VAPOUR DEPOSITION (PVD) COATING

Do the arms of your black windscreen wipers use this colouring process? Well, no. The rich, glossy black used to be from immersion of stainless steel in molten sodium/potassium dichromate at 400oC for about 30 minutes but is now usually replaced by a 180oC cured organic coating. Shorter immersion times were used for thermal solar water heaters but they are now either painted or plastic - although black chrome has had a place in the market. The second major method of colouring stainless steel is PVD or Physical Deposition of a Vapour – hence PVD. The process is carried out in a high vacuum chamber with a small amount of (usually) argon gas. The gas is ionized by a high negative voltage on the target and forms a plasma of electrons and positive ions which bombard the source metal and ejects (or sputters) metal ions or atoms. These are deposited on the product to form a thin (typically 300nm) coating on the clean product. It is critical that the coated surface is free from contaminants or the coating will lack adhesion. It is routinely used to hard coat small objects like drills but, on a larger scale it produces coloured door furniture or objects whose size is only limited by the vacuum chamber. Coating larger objects and sheet material requires greater electron ionization efficiency in the plasma which typically uses magnetic fields parallel to the surface of the target.

The source metal can also be generated by thermal evaporation but this is less common.

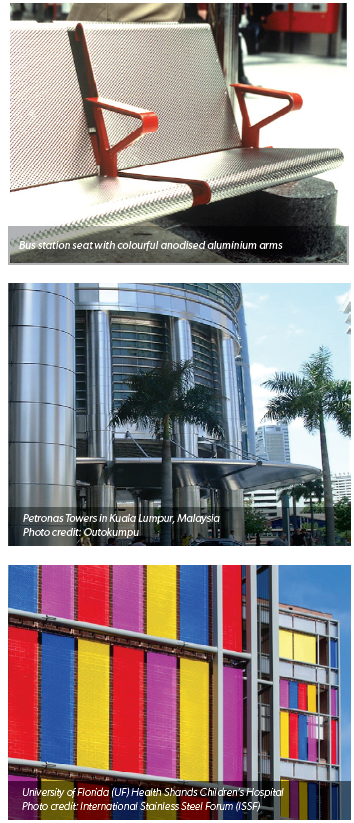

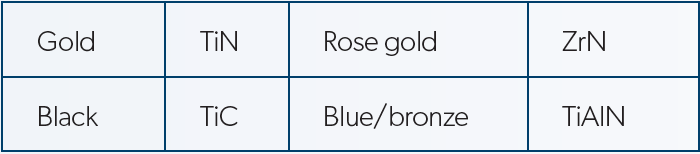

Unlike the electrochemical INOX process, the colour of the PVD coating is determined by the source material with a few examples shown in the table. It is also invariant with viewing angle. PVD coatings are much more abrasion resistant than the INOX system but are not indestructible.

PATTERNED STAINLESS STEEL: SURFACE TEXTURE AND ITS EFFECT

A range of embossed, patterned and textured stainless steel finishes are available. Hot rolled finishes are usually too dimpled for aesthetic finishes. Cold rolled mill finishes are smooth and either dull grey (2B) or very bright (BA – bright annealed) and provide differing basic appearances but the same mechanical properties. Both have significantly better corrosion resistance than as-abraded finishes. Aesthetic changes by abrasion or blasting will provide feature finishes but have only minor effects on the colour and mechanical properties although rough as-abraded surfaces are known to be less corrosion resistant, i.e. the 0.5 micrometre Ra criterion.

Mechanically embossed profiles on austenitic mill rolled finishes might reduce the cleanability, but they also increase the strength because of cold work strengthening - while retaining the base metal corrosion resistance. This strengthening means that thinner material can be used, such as the thin checker sheet used in toolboxes – good visuals and lower weight in the utility with security for tools. Profiled sheet for outdoor public seating is another application with thinner sheet because of the strength and a bright appearance without glare.

High-wear areas such as airport baggage collection or hospital corridors often use rigidised stainless steels where a through sheet profile significantly increases strength and stiffness with a pleasing aesthetic. An added advantage for profiled finishes is that scratches only affect the peaks and are less apparent partly because they are not continuous. On a grander scale, the Petronas Towers in Kuala Lumpur, Malaysia is a more complicated Cambric profiled finish on a base 316 metal with BA stock. The profiled finish is to avoid blinding reflections while using a 316 base metal with a mill finish that has the highest corrosion resistance available.