FAQ 10: Thermal Expansion and Design of Stainless Steel Fabrications

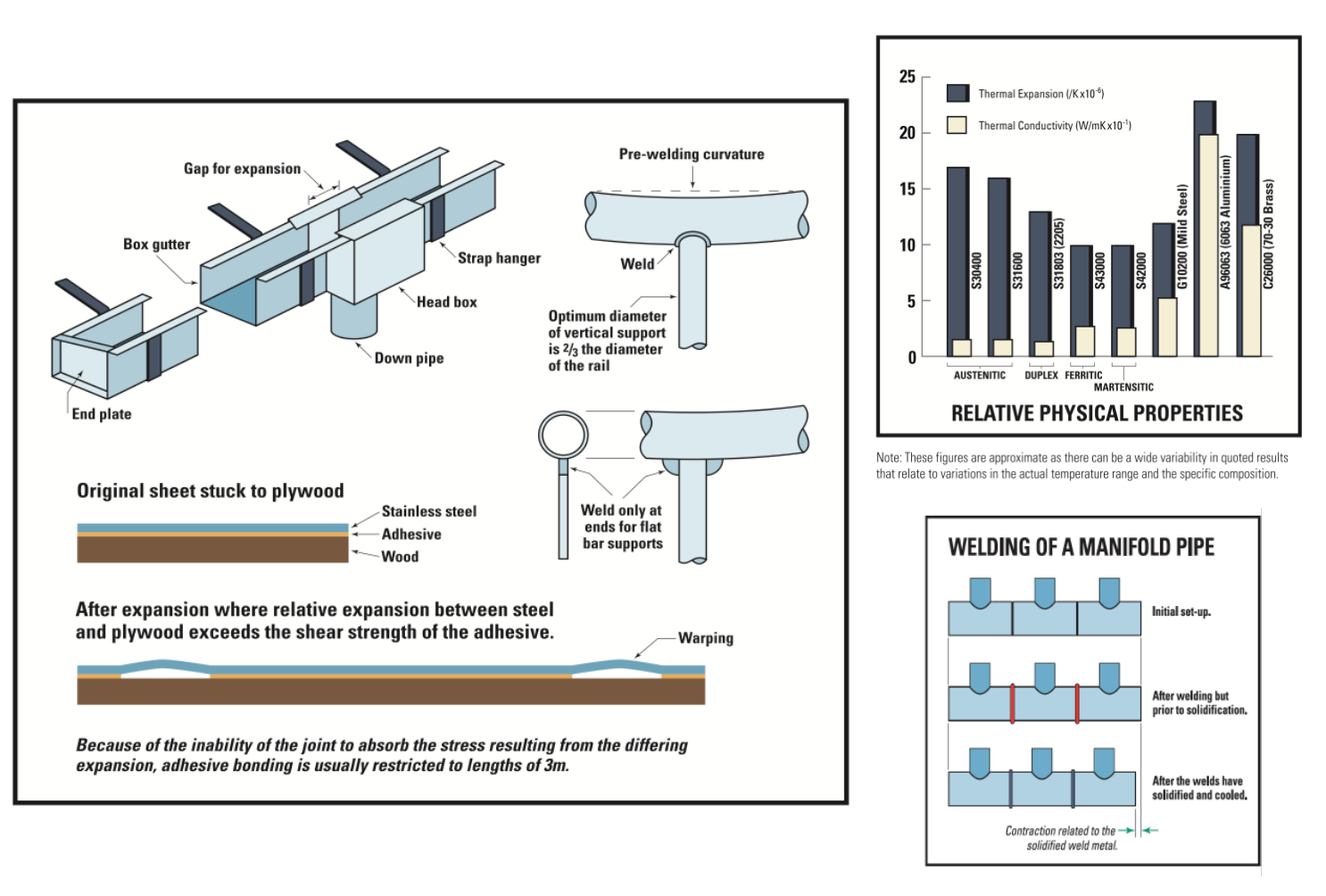

Either while being welded or glistening in the summer sun, the three major families of stainless steel behave differently to each other, carbon steels, aluminium and copper alloys because, as shown in the bar chart, the coefficient of thermal expansion and conductivity - and their ratio - varies.

Download ASSDA Technical FAQ 10 (PDF)

While alloys of copper and aluminium have equal or higher coefficients of expansion than austenitic stainless steels, it is the unique combination of high thermal expansion and low thermal conductivity that necessitates special precautions and procedures in the design and fabrication of the most commonly used 304/304L and 316/316L grades of austenitic stainless steel in structures and vessels. Information on handling other families of stainless steels is given in ASSDA’s Australian Stainless Reference Manual.

DISTORTION DURING WELDING

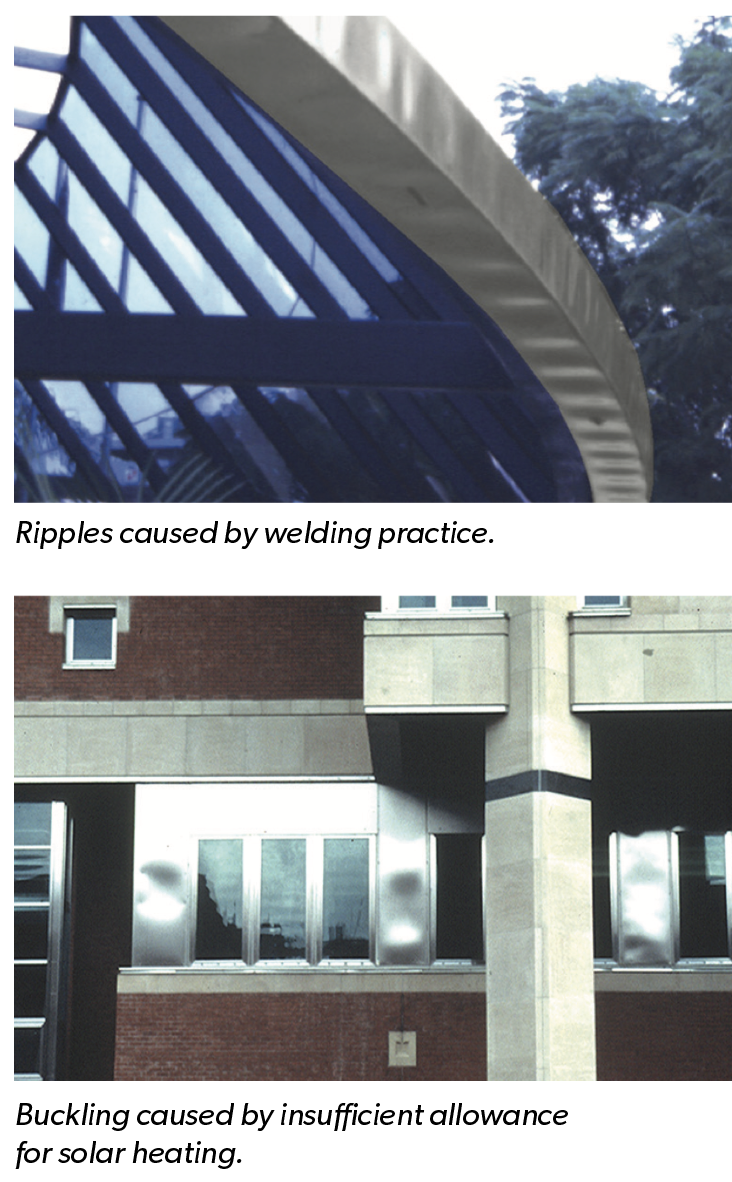

Failure to address thermal expansion and conductivity can result in severe distortion during welding, as differential expansion causes the heat generated by the welding process to remain localised, causing steep temperature gradients and high localised stresses or surface distortion. Standard welding procedures should be adopted to minimise heat build-up in the weld zone. These include using minimum amperage consistent with good weld quality and controlling interpass temperatures using guidelines provided in Table 5.10 of AS/NZS 1554.6. Clamping jigs with copper or aluminium backing bars as heat sinks on the welds may also be feasible. Other precautions to minimise distortion during welding include efficient jigging or the use of an ends and middle sequence of closely spaced tack welds rather than a straight run. The wrinkled guttering below illustrates the shrinkage problems of poorly planned welding.

The Design Manual for Structural Stainless Steel2 indicates that austenitic stainless steels suffer from the same types of distortion during welding as carbon steel, but the higher coefficient of expansion (17 μm/m°C versus 12 μm/m°C for carbon steel) and the lower thermal conductivity (approximately 30% of carbon steel) increase distortion of austenitic stainless steel weldments. Duplexes are between carbon and austenitic stainless steels in thermal expansion coefficient, but the thermal conductivity is similar to austenitics so heat control is still important. Ferritic stainless steels have similar thermal welding properties to carbon steel but require more skilled welders for metallurgical reasons.

The Design Manual also suggests that a number of additional actions can be considered by both the designer and the fabricator to minimise welding distortion and mismatches such as illustrated in the manifold. These include designing with symmetrical joints, designing to accommodate wider dimensional tolerance, reducing cross-sectional area of welds in thick sections (e.g. replacing Single ‘V’ preparation by Double ‘V’ or Double ‘U’), ensuring that good fit-up and alignment are obtained prior to welding, and using balanced welding and appropriate sequences such as ‘backstepping’ and ‘block’ sequences.

EXPANSION PROBLEMS AFTER INSTALLATION

Another problem arising from the high coefficient of expansion of austenitic stainless steels compared to plywood is differential expansion – although water uptake may also be an issue. In the illustrated case of stainless steel bonded to plywood by adhesive, a maximum length of 3 m is recommended to avoid failure of the adhesive bond during thermal cycling.

Another problem is when panels (even quite small ones) are in full sun and do not have expansion room for the movement since they were installed at (say) 20 °C to the 40 °C day plus 30° C overheated metal.

In architectural applications with long runs such as profiled roofing, expansion clips should be used to permit thermal movement without localised buckling and failures. As with other metal roofing and cladding systems with runs 3-9 m or longer, there are limits to the maximum width of formed profile for the thickness of stainless sheet used. The formed profile must have sufficient columnar rigidity and strength to transform thermal expansion stresses into sliding movement in the expansion clips. For longer runs, expansion joints should be provided every 7-12 m, with clearances of 6mm at vertical faces and 12 mm where a gutter end abuts a wall. The publication Stainless Steel in Architecture, Building and Construction - Guidelines for Roofs, Floors and Handrails3 illustrates roofing fixtures for roll-formed profiles and the traditional standing seam and batten roll types. In contrast, ferritic guttering and roofing have similar properties to carbon steels with about 62% of the expansion of an austenitic structure.

In stainless steel piping systems, thermal expansion stresses can cause rupture of the support points, buckling of the pipe, or breakage of equipment connected to the piping if the changes in dimensions are not absorbed by expansion joints or flexibility of the piping installation. The Piping Manual for Stainless Steel Pipes for Buildings4 provides a guide to assessing thermal stresses and reactions at supports and anchor points, as well as a guide to determining if the flexibility of piping can absorb its expansion. The latter involves an empirical formula which requires that the piping anchor points are at the pipe’s ends, the piping system has no branches, and there are no changes along the length of the pipe (e.g. diameter, thickness, material quality, temperature, etc.). If the flexibility cannot absorb the thermal expansion displacement, then expansion joints, flexible joints or ball joints should be used (after a computer stress analysis of the joint).

CONCLUSION

Thermal expansion and conductivity are critical determinants when designing and fabricating austenitic stainless steel products and are still important with duplex stainless steels. Early consideration of these elements will ensure a better and longer-lasting product, both aesthetically and structurally.

REFERENCES

- ASSDA's Australian Stainless Reference Manual.

See also: Avery, R.E. & Tuthill, A.H. (1992) Guidelines for the Welded Fabrication of Nickel-Containing Stainless Steels for Corrosion Resistant Services (Nickel Institute Publication No. 11007), and International Molybdenum Association (IMOA)'s Guidelines fo the Welded Fabrication of Duplex Stainless Steels, 3rd edition (2014). - Design Manual for Structural Stainless Steel, 4th edition (2017): www.steel-stainless.org/designmanual.

- Cochrane, D.J. (1994), Stainless Steel in Architecture, Building and Construction - Guidelines for Roofs, Floors and Handrails (Nickel Institute Publication No. 11013).

- Nickel Institute and Japan Stainless Steel Association (1987), Piping Manual for Stainless Steel Pipes for Buildings (Nickel Institute Publication No. 12008).