Quick and easy tips for keeping that shine

Retaining a sparkling finish on stainless steel surfaces is just a matter of a few simple steps. And you don't need expensive products or special equipment - ordinary household cleaners are usually all that's required. You just need to bear in mind a few easy DOs and DON'Ts...

It'll come out in the wash

Stainless steel looks best if it's cleaned regularly with plenty of water. Drying afterwards makes sure streaky marks aren't left behind.

Remember that simply wiping with a damp cloth is not as effective as it can smear dirt without removing it.

Routine cleaning prevents any stubborn stains building up.

So what will you need?

You don't need any fancy equipment. For day to day cleaning, plenty of water, some mild detergent and a cloth or soft brush will do the job. You can use a 1% ammonia solution but don't use bleach? it's just too easy to make the solution too strong and too hard to rinse it properly afterwards.

After washing, rinse in clean water and wipe the surface dry with a soft absorbent cloth. On brushed stainless steel, follow the direction of the polish for best results.

An excellent cloth to use is 3M's Scotch-Brite high performance cleaning cloth.

Watch out for scratches!

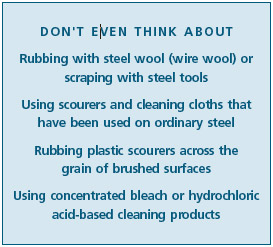

The important thing to remember is that stainless steel can be scratched by careless handling or aggressive scrubbing. Just like you would take care of a polished timber finish, avoid dragging rough items across the surface and be aware that grit trapped under other objects can be the culprit.

Avoid bad chemistry

Stainless steel may discolour if left in contact with salts or acids for extended periods. Also avoid leaving carbon steel items in contact with stainless steel, particularly if wet. But if you observe ordinary hygiene measures, like timely cleaning-up in food preparation areas, you won't have any problems.

How to handle the tough customers

How to handle the tough customers

Sometimes you need a tougher approach. Here's how to get rid of the most common offenders:

Fingerprints, oil & grease marks

If a mild detergent or dishwashing detergent doesn't shift unsightly fingermarks, get rid of them with a bit of glass cleaner on a soft cloth. You can also use a small amount of alcohol, methylated spirits, acetone or mineral turpentine. Then rinse with clean water and dry.

You can give longer protection to high traffic areas by lightly rubbing with olive oil or baby oil followed by a polish and shine using a soft cloth.

Tea & coffee stains

Discolouration from tea and coffee stains can be removed by soaking in a solution of boiling water and baking powder. Remember to rinse well and wipe dry.

Sticky labels

Remove sticky labels as soon as possible. Gentle heat from a hair dryer or a glue gun generally softens the glue for easy removal, or you can warm stainless steel pots and pans in the oven before peeling off the labels. Eucalyptus oil based cleaners (or eucalyptus oil on its own) often work well to remove adhesives.

Ensure you don't leave any glue on the surface ? it could trap dirt or break down and cause staining.

Rust marks

Apply cream cleanser with a soft damp cloth and rub gently.

If the mark still won't shift, it might be necessary to use a proprietary stainless steel cleaner. These are usually based on dangerous chemicals (such as phosphoric, oxalic or sulphamic acids) and must be handled with care according to the manufacturer's directions.

After cleaning it is important to neutralise the acid with a 1% ammonia or baking powder solution, rinse with clean water and wipe dry. If the rust has worn away the surface, don't despair! Bad rusting can be repaired with professional polishing but you will need to get expert advice.

Paint

Apply paint stripper, taking care to follow the safety instructions. You may need to use a nylon brush or scouring pad, but avoid metal scrapers at all costs - they will damage the surface.

Hard water scale

Heavy limescale from hard water can be loosened by soaking in a hot water and 25% vinegar solution. Rinse well with a solution of baking powder or 1% ammonia and then with clean water. Always wipe dry.

Cement and mortar

Cement and mortar splashes should be washed off before they set. Mild acids such as vinegar may be needed but not those using chloride rich chemicals. Never use brick cleaning liquids which contain hydrochloric acid. Be very careful that loosened particles don't scratch the steel surface.

Don't go against the grain

Always rub stainless steel in the same direction as the grain. Rubbing against the grain will spoil the finish and stainless will lose its shine. Worse, rubbing against the grain can damage the surface by creating microscopic crevices where dirt can collect. This can lead to corrosion spots.

Fortunately, it's usually easy to tell which is the right direction. You need to watch out for items like round handrails, which are often polished around their circumference when they're manufactured, rather than up and down the length of the tube.

If you have to scrub a stain to remove it, make sure you use a clean nylon scourer or a cloth with chalk-based cream cleaner. But test an inconspicuous area first as you could end up with a bright polished spot which doesn't match the rest of the surface.

NEVER EVER use steel wool (wire wool) to clean stainless steel.

It is usually made of carbon steel and any fragments left behind will rust onto the stainless steel surface. Using any kind of scourer which has previously been used on ordinary (carbon) steel is also a no-no for the same reason.

Stainless steel wool scouring pads are available for heavy duty work, like removing burnt food from stainless steel saucepans. These will scratch the stainless steel surface, but won't leave fragments to go rusty.

Important Disclaimer

The technical recommendations contained in this publication are necessarily of a general nature and should not be relied on for specific applications without first securing competent advice. Whilst ASSDA has taken all reasonable steps to ensure the information contained herein is accurate and current, ASSDA does not warrant the accuracy or completeness of the information and does not accept liability for errors or omissions.

This article featured in Australian Stainless Issue 21 - June 2002.