Stainless steel is used for a wide range of structural applications including:

-

Beams, columns, platforms and supports in processing plant for the water treatment, pulp and paper, nuclear, biomass, chemical, pharmaceutical, and food and beverage industries;

-

Primary beams and columns, pins, barriers, railings, cable sheathing and expansion joints in bridges;

-

Entrance structures, canopies, cladding and support systems for masonry;

-

Security barriers, blast walls, hand railing and coastal structures.

Case studies of a range of structural applications are available at the case studies section of www.teamstainless.org/resources/information-center-for-stainless-steel-in-construction.

This introduction to structural design in stainless steel aims to highlight differences between the material properties and structural behaviour of stainless steel and conventional carbon steel normally used for structural purposes, e.g. grade 350 to AS 3678 and AS 3679.

It should be noted that stainless steel structures should not be simply designed using design standards for carbon steel, such as AS 4100 and AS 4600, because of the significant differences between the mechanical properties of carbon and stainless steels.

Selection of an appropriate alloy of stainless steel is the first step in any design process.

Austenitic stainless steels are most widely used for structural applications, though the use of duplex stainless steels is increasing, where it is possible to exploit the benefit of high strength (around 460 MPa, compared to a strength of around 220 MPa for austenitic stainless steels). This can be particularly valuable in weight-sensitive structures like bridges or on offshore topsides. Duplex stainless steels are more likely to be used in heavier gauges. Ferritic stainless steels are also suitable for structural applications, offering a corrosion resistant alternative to many light gauge galvanised steel applications. They are generally used in gauges of 4 mm and below although the 12% chromium utility alloys are used in thicker sections (vehicle chassis or high temperature ducting) when minor rust staining can be allowed.

Material properties

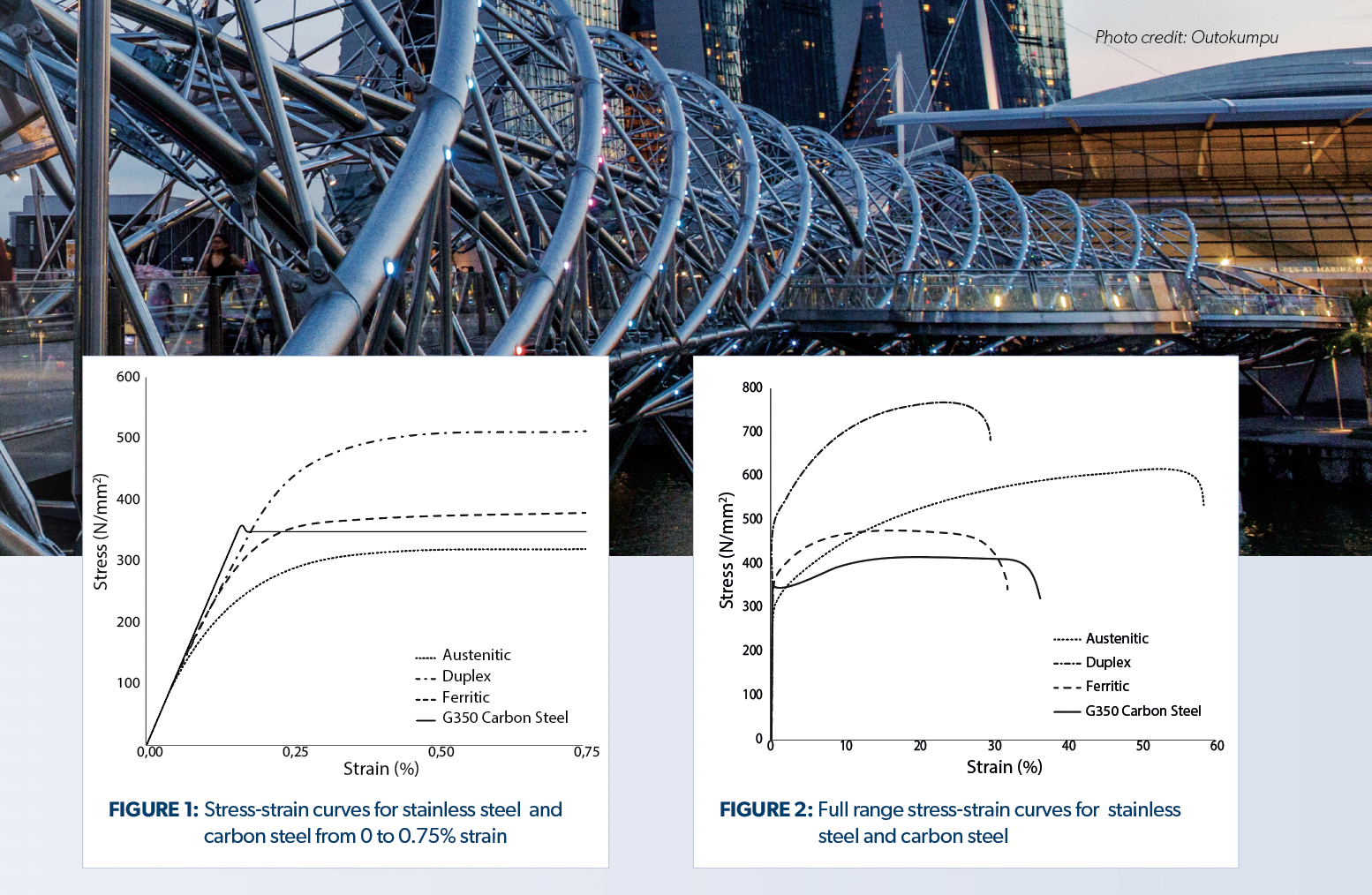

From a structural viewpoint, the main property that distinguishes stainless steel from carbon steel is the stress-strain response. In contrast to carbon steel, for which the stress-strain curve may be modelled as bi-linear for most compression and flexural member design purposes, the stress-strain curve of stainless steel is generally highly non-linear and without a distinct yield point. Figure 1 compares the stress-strain characteristics of various stainless steels with carbon steel for strains up to 0.75% and Figure 2 shows typical stress-strain curves to failure. (The figures show stress-strain curves which are representative of the range of material likely to be supplied and must not be used in design.) The distinctive mechanical properties - considerable strain-hardening and ductility - make austenitic and duplex stainless steel particularly well suited for structures required to withstand accidental loading due to their high energy absorption characteristics.

In the absence of a clear yield stress, it is common practice to define an equivalent yield stress for stainless steel by using a proof stress, usually the 0.2% proof stress. (By definition, the plastic - or permanent - strain at 0.2% proof stress is 0.2%.) The proportional (or linear) limit of stainless steels’ deflection ranges from 40 to 70% of the 0.2% proof stress.

As a result of the non-linearity, stainless steel loses stiffness at low stress levels. This affects the design rules for members that rely on stiffness to transfer loads, notably compression members and unbraced flexural members.As well as nonlinearity, the stress-strain characteristics of stainless steel also display non-symmetry between tensile and compressive behavior and anisotropy, i.e. differences in behaviour of coupons aligned parallel and transverse to the rolling direction. In general, anisotropy and non-symmetry increase with cold work and so are more significant in the design of lighter gauge heavily worked sections, rather than thicker walled structural sections.

It is possible to enhance the strength of austenitic stainless steel by cold-working to a much greater extent than for carbon steel.

The initial modulus of elasticity (Eo) of stainless steel alloys is slightly lower than that of carbon steel.

The behaviour of stainless steel at elevated temperatures differs to that of carbon steel because of the metallurgical differences caused by the composition. Stainless steel retains a greater proportion of its strength at temperatures above about 550 °C and shows better stiffness retention at all temperatures, which is important in design against fire for components such as blast and fire walls.

The coefficients of expansion (CTE) of austenitic stainless steel alloys are larger than those of carbon steel. At the same time, the thermal conductivity is lower. While the CTE is important in determining thermally induced stresses and deformations, the combination of larger coefficient of expansion and lower thermal conductivity has the effect of substantially increasing the risk and possible extent of welding distortions than those experienced in fabricating carbon steel structural member. The duplex grades have similar thermal conductivity to the austenitics but with 20% lower CTE so the risk of welding distortion is slightly lower than with austenitics.

Specifications and reference documents for design of stainless steel structures

American Society of Civil Engineers (ASCE) has revised ASCE 8 Specification for the design of cold-formed stainless steel, applicable to lighter gauge austenitic and ferritic material in the annealed and temper-rolled condition (Reference 1). The 2002 version has been substantially updated because of extensive research work and will be issued late in 2021. This includes alternative treatments of compressive loading, i.e. effective width and direct strength. The structure of AISC 8 will be familiar to those using AS/NZS 4673:2001 although 4673 has now been withdrawn as an aged standard.

Also in 2021, the American Institute of Steel Construction (AISC) will release a new standard (reference 2) AISC 370 Specification for Structural Stainless Steel Buildings to reflect the substantial increase in the use of heavy structural stainless steel sections. It includes hollow sections as well as welded, hot rolled and bar products. It will be accompanied by AISC 313 Code of Standard Practice for Structural Stainless Steel Buildings (Reference 3) and an updated 2nd Edition of the 2013 AISC Design Guide 27: Structural Stainless Steel.

The Eurocode for stainless steel design, EN 1993-1-4, covers welded, hot rolled and cold formed products made from austenitic, duplex and ferritic alloys, at room temperature and in fire (Reference 4). The Design Manual for Structural Stainless Steel (4th Edition) was published in 2017 and gives essential information needed by designers concerning alloy selection, durability, material properties, design rules and fabrication, in accordance with EN 1993-1-4 and other European standards (Reference 5). A Commentary explains how the design expressions in the Recommendations were derived and gives background information and references. Design Examples demonstrate the use of the Recommendations. Section property and member capacity software is also available, all aligned to EN 1993-1-4.

This Design Manual and these supporting design tools are freely downloadable from www.steel-stainless.org/designmanual.

This article has been extracted from the 2020 Australian Stainless Reference Manual, available for purchase at assda.asn.au

REFERENCES: 1. ASCE 8-02 Specification for the Design of Cold-Formed Stainless Steel Structural Members, SEI-ASCE 8-02. \ 2. AISC 370-2021 \ 3. AISC 313-2021 \ 4. EN 1993-1-4:2006+A1:2015 Eurocode 3. Design of steel structures. General rules. Supplementary rules for stainless steels. \ 5. Design Manual for Structural Stainless Steel, SCI Publication P413, The Steel Construction Institute, (available from https://steel-sci.com/european-design-manual-for-structural-stainless-steel.html).

This article is featured in Australian Stainless Magazine issue 72, 2021.