Brisbane’s Kingsford Smith Drive upgrade saw Australia’s largest use of stainless steel reinforcement bar to date, transforming the structural performance of one of the city’s busiest roads.

An initiative of Brisbane City Council and designed and constructed by Lendlease, the Kingsford Smith Drive upgrade involved widening the 7km road from four to six lanes between Theodore Street at Eagle Farm and Cooksley Street at Hamilton. This was achieved via a retaining wall built between 10m to 15m out into the Brisbane River. As a major road corridor, Kingsford Smith Drive links the Brisbane CBD to Brisbane Airport, the Port of Brisbane and residential and economic growth areas including Northshore Hamilton and the Australia TradeCoast region. Planning for future traffic volumes, construction commenced in 2016 to deliver increased road capacity and improved public transport, pedestrian and cycle facilities.

Critical to the upgrade and structure was the extensive use of stainless steel. ASSDA Member Valbruna Australia supplied 800t of grade 2304/1.4362 Reval® stainless steel in 12mm, 16mm and 20mm stainless steel reinforcement bar (rebar), which was used in the tidal zone to 1m above the Highest Astronomical Tide (the splash zone) of the precast fascia panels and in the lowest of the precast cantilever panels that fell within the splash zone.

The Brisbane River is a tidal estuary, and duplex stainless steel reinforcement meets the service life demands of structures in a brackish water environment. Stainless steel reinforcing resists chloride attack and pitting corrosion, and when specified correctly, provides a minimum service life of 100 years in concrete, reducing life-cycle costs. Kingsford Smith Drive carries an average of 70,000 vehicles per day, and stainless steel rebar delivers confidence in the strength, durability and structural performance expected of critical public infrastructure.

The scheduling, cutting and bending of the stainless steel rebar to tight precast tolerances was performed by Mesh & Bar. Furthermore, Valbruna supplied approximately 5,000 grade 2205 stainless steel terminator couplers, used to simplify rebar placement and create anchorage within the concrete.

Stainless steel was also delivered in spades for various other components of the project, with ASSDA Member and Accredited Fabricator Stainless Engineering Services engaged for the fabrication and installation services. Forty-two road bridge expansion joints were fabricated in their workshop using 15t of grade 2205, 10mm and 16mm stainless steel plate, with material supplied by ASSDA Member Stirlings Performance Steels. The cantilever bridge deck was constructed in 40m long concrete sections, and the expansion joint fixings were countersunk and bolted insitu to deliver a continuous smooth surface.

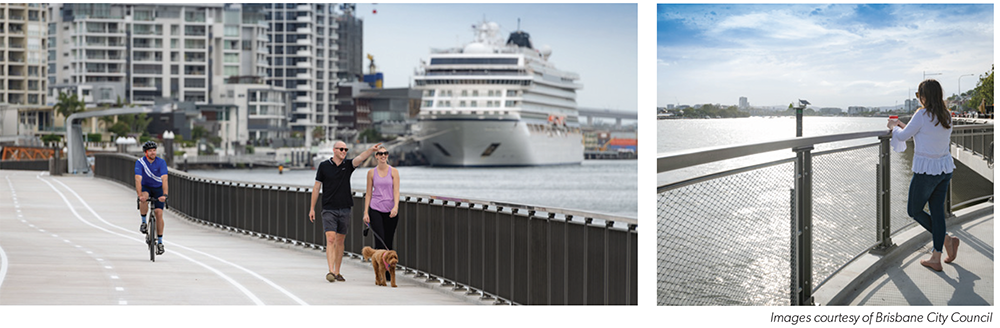

Additionally, Stainless Engineering Services delivered 1.5km of stainless steel top rails for the Lores Bonney Riverwalk, Kingsford Smith Drive’s riverside promenade. The riverwalk meanders from Bretts Wharf to Cameron Rocks Reserve and the top rail was specified to follow the flow of the river, presenting several challenges in its fabrication and installation. Furthermore, the top rail was specified to be delivered in 10m lengths. It was TIG-welded on-site using grade 316 stainless steel 150x50x5mm rectangular hollow sections (RHS) with a 600-grit finish supplied by Stirlings Performance Steels. Different methods were trialled to achieve the curve specified and conventional manual means were applied to bend the RHS in-between the posts.

Stainless Engineering Services fabricated the stainless steel spigots from 32mm plate to suspend and clamp the galvanised balustrade panels, as well as other various stainless steel components including planter boxes, rung ladders for sewer and drainage manhole access and cover plates at all expansion joints along the boardwalk.

Stainless steel tube was also used for 300m of pedestrian and bike rails at Cameron Rocks Reserve, with material supplied by ASSDA Members Australian Stainless Distributors and Midway Metals.

With the Brisbane River at its doorstep, the use of stainless steel throughout the project has delivered several key benefits in ensuring the longevity of public infrastructure in a marine environment. Structural durability, corrosion resistance and visual appeal are just some benefits that stainless steel has contributed to the precinct’s improvement and development.

Completed in 2020, the Kingsford Smith Drive upgrade has delivered up to 30% travel time savings for all vehicles, 7km of new and improved pedestrian and cycle paths, and enriched urban amenities and green spaces for locals and visitors.

This article is featured in Australian Stainless Magazine issue 74, 2022.