Minimising mining (primary production) and maximising recycling (secondary production) are core principles of sustainable resource management. Consequently, there is an increasing interest in quantifying the material life cycle of stainless steel and its efficiencies from production to fabrication, manufacturing, use, recycling and, in some cases, disposal.

In 2006, Team Stainless and Yale University started the first project to quantify stainless steel stocks and flow cycles. In 2022, The Karlsruhe Institute of Technology made a more detailed analysis of 2019 data covering 50 countries, territories, and regions.

Stainless steels: A sustainable solution for more than a century

Stainless steels are procured in various grades and support many essential applications in our modern world from transportation, buildings, bridges, water pipes and industrial processes to medical uses, food processing and preparation. They are often selected as the sustainable material of choice for a myriad of domestic and industrial applications because of their recyclability, strength, toughness, durability, hygienic properties, and resistance

to corrosion, heat, cold and blasts.

2019 global production and apparent consumption

In 2019, global stainless steel meltshop production was 52.2 million tonnes, with more than half being produced in China (29.4 million tonnes). Use in fabrication was estimated to be 43 million tonnes, 46% of which was in China.

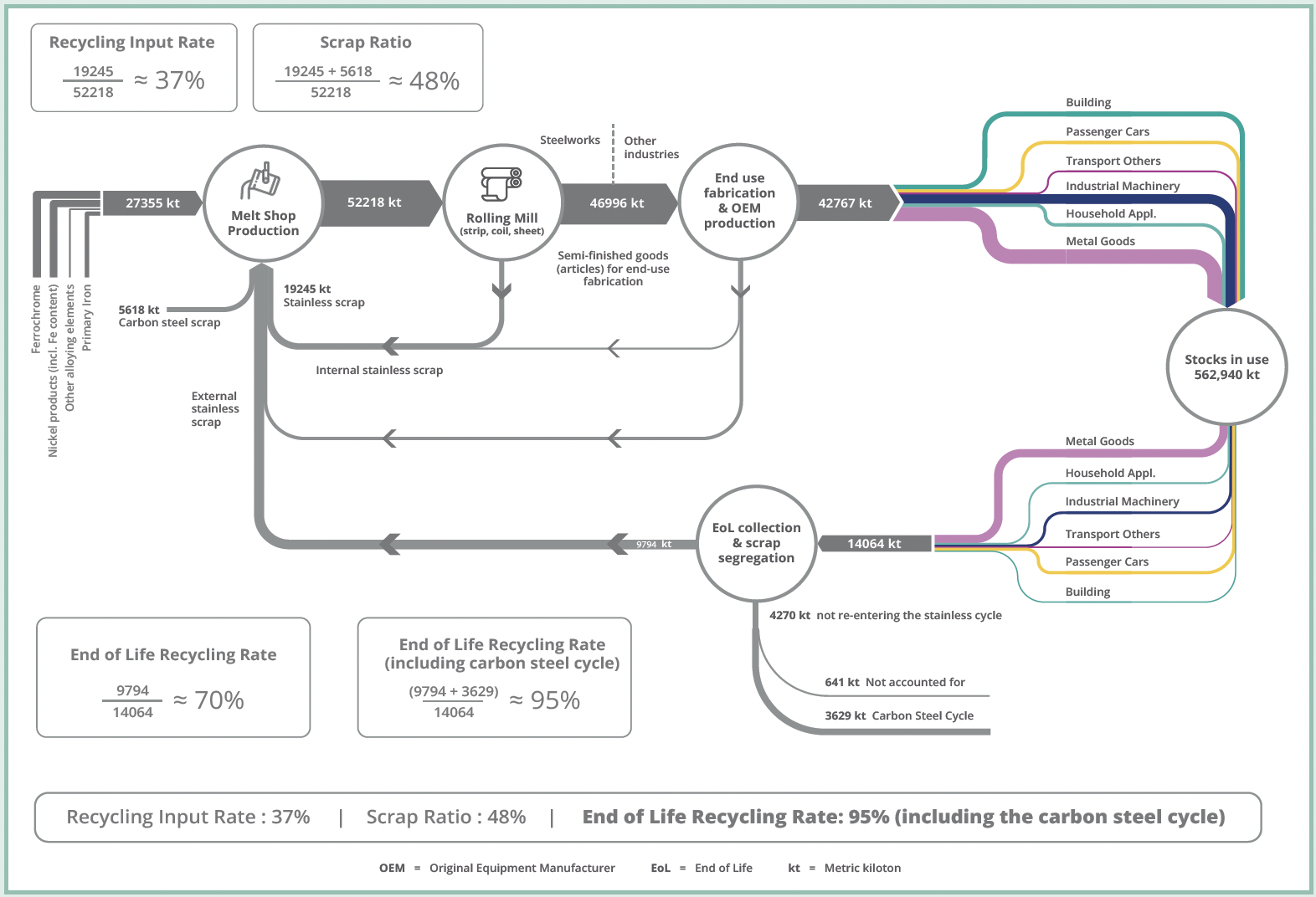

Global stainless steel flows for 2019

The Sankey diagram below shows the life cycle of stainless steel from input of raw materials through steelmaking to fabrication of items in various end-use sectors. It also shows the flow of stainless steel scrap to make new stainless steel or carbon steel. (2019 data)

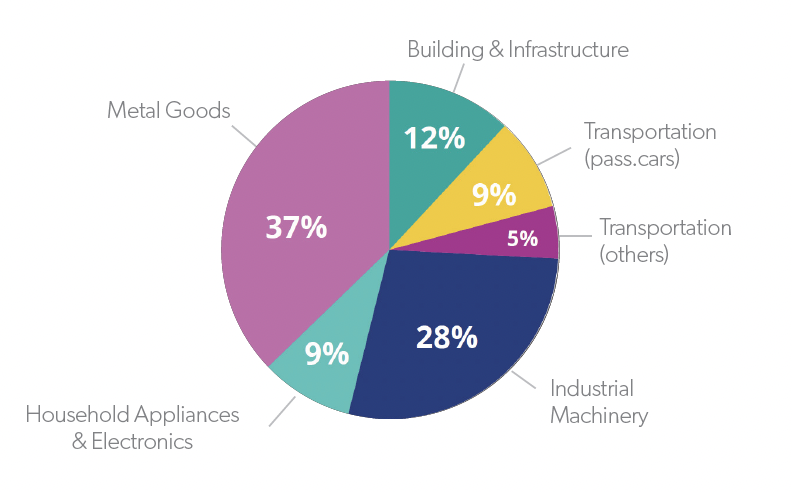

2019 end use

End use refers to the final products where stainless steels are used. Stainless are used by many sectors, in many countries and in a multitude of end-use products, remaining in use for a few years to many decades.

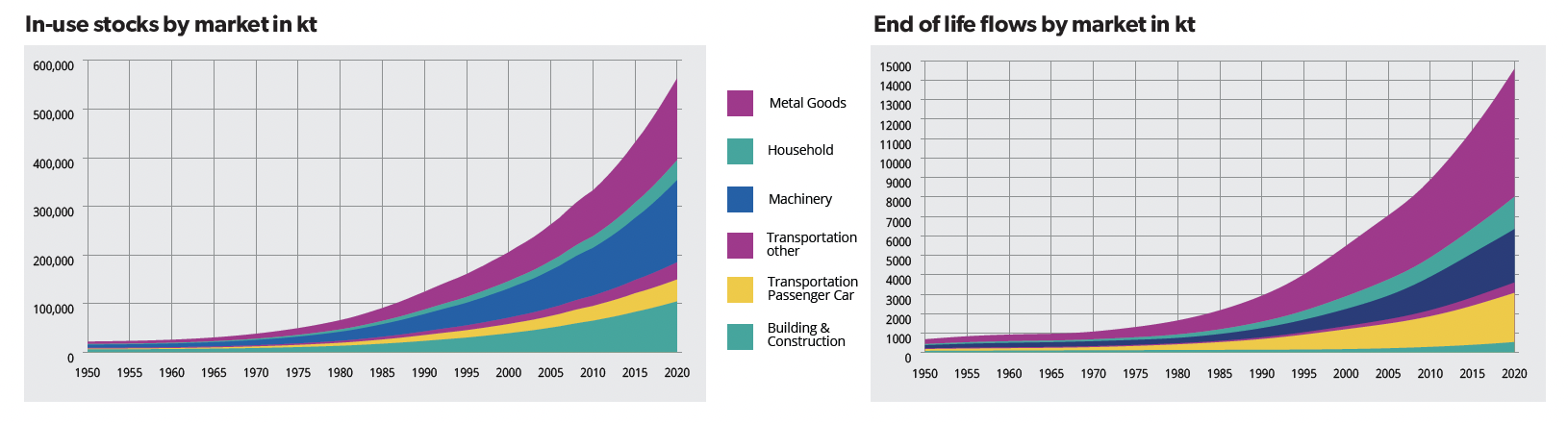

In-use stocks by market in kt

The global stainless steel volumes currently in use, by end-use sectors, e.g., exhaust systems in cars or cutlery in metal goods. This stainless steel will be returned as scrap at the end of the product’s life.

End-of-life flows by market in kt

The global stainless steel end-of-life volumes collected, processed and available for recycling. Scrap is melted and transformed into new sustainable stainless steel products which can in turn be recycled at the end of their life.

2019 stainless steels end-of-life recycling rate

Recycling is highly beneficial, economically and environmentally. The high value of stainless steel scrap makes it worth collecting and sorting, and is the reason why it is recycled at such a high rate. Reusing its valuable alloying elements reduces cost, resource depletion, environmental impacts and energy use. The high end-of-life recycling rate indicates how efficiently stainless steel is recycled from end-of-life products.

In principle, and as long as product design and recycling technologies allow, stainless steels can be recycled infinitely. Scrap is a secondary raw material arising from the product manufacturing processes as well as from finished products at the end of their life.

2019 recycled content of stainless steels

The global recycled content of stainless steel, known as scrap ratio, is 48%. This global figure is influenced by the regional and country ratios.

Scrap ratios vary according to the stainless steel production process and range from the electric arc furnace route with high scrap ratios to the blast furnace route with lower ratios. Also relevant is the maturity of a market. In mature markets e.g., Europe, the USA or Japan, a high availability of scrap can be found because stainless steel products were already manufactured many decades ago and are now at the end of their lifetime. They are now returning to the market as stainless scrap, a very valuable raw material. In less mature markets such as China where large-scale production began only 15 years ago, the end-of-life of stainless steel products has only just begun. Accordingly, scrap availability is limited in less mature markets and other production processes that use less scrap have to be employed to meet consumer demand.

This article was originally published by Team Stainless, an informal alliance of the European Ferrous Recovery and Recycling Branch, Eurofer, the International Chromium Development Association, the International Molybdenum Association, the International Nickel Study Group, the world stainless association, and the Nickel Institute.

This article was featured in Australian Stainless Magazine Issue 79 (2024).