Advanced engineering solutions are required to handle conditions found on offshore drilling and processing platforms. The saltwater environment is highly corrosive, the flare presents extremes of temperature and the force of winds and currents is constant. The most durable and reliable materials need to be employed, which is why stainless steel plays and important part.

Stainless for power generation

At a time when so many industrial processes are computer-driven, there is still a place for human knowledge and experience in the highly specialised area of hydro-turbine manufacturing.

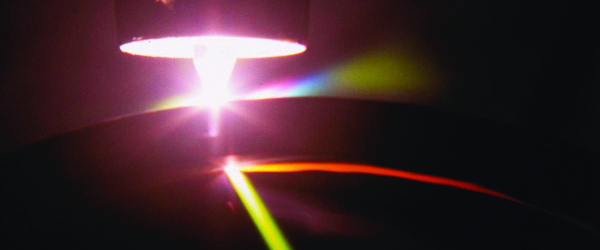

Keyhole Welding

Savings for Stainless

Posted 30 November 2003

Researchers from the Commonwealth Scientific and Industrial Research Organisation (CSIRO) and the Cooperative Research Centre for Welded Structures (CRC-WS) have developed a welding process for stainless steels and other corrosion-resistant metals that is significantly faster, cheaper and easier than current practices.

Specifying Stainless Steel Pressure Piping for High Rise Buildings

Brisbane's tallest residential tower, The Aurora will stand 69 levels and will set an important precedent in the use of stainless steel pressure piping in high rise buildings when the Bovis Lend Lease project is completed in January 2006

Reducing risk with stainless flameproof technology

Where flammable or combustible materials are stored or handled, there can be a severe risk of an explosion or fire if handling equipment such as forklift trucks are not flameproofed.

Stainless Steel Bulk Solvent Storage Facility Completed

When coatings manufacturer, PPG Industries’ original bulk solvent storage facility had come to the end of its economic life, the company elected to install a new $8m facility that is both efficient and fully compliant with numerous safety, environmental and good design principles on its Clayton, Victoria site

Alloy C-276: A Super Alloy for Processing Plants

OMG Cawse Pty Ltd is the owner and operator of a nickel and cobalt mining operation and processing plant that is located 55 kilometres north east of Kalgoorlie.

Australian Stainless Products

Built on Reputation

Alistair Patterson has a flair for the food and beverage industry that borders on obsession. As the sole proprietor for ASSDA Accredited Fabricator, Australian Stainless Products, Patterson's reputation within the industry means when projects are on, he is onto it!

Nickel Mine Uses 400 Tonnes of Stainless Steel

When ASSDA Accredited Fabricator Nepean Engineering was awarded the tender for the manufacture of the stirring mechanisms for 10 thickeners for the Goro Nickel Mine in New Caledonia, they had no idea of the enormity of the venture. But having now completed the two-year undertaking they reflect on what has been their biggest stainless steel project to date.

Stainless advance for water treatment plant

Never has there been a time in Australia when water preservation was so critical. As populations rise and dam levels fall, the importance of treating and reusing water has become not a question of “if” but a question of “when”.

Stainless Steel and Plumbing Standards

After three years of development, the first stage of a Standard covering the grade and dimensions of stainless steel pipes and tubes suitable for water supply and drainage systems has been completed. This interim Standard will be converted to a full Australian Standard in 2009.

Stainless Refinery First of its Kind

Stainless frameless tankers make big Australian debut

McColl's Transport carts a variety of chemicals such as caustic soda and formaldehyde. The tanker barrel has been wrapped and not rolled, with full length stainless steel sheets used to eliminated circumferential welds. There’s a new breed of tanker being put through its paces along Australia’s east coast carrying aggressive chemicals and class three petroleum products for McColl’s Transport.

Grade 431

A versatile, high strength martensitic stainless steel

Martensitic stainless steels are a less well-known branch of the stainless family. Their special features – high strength and hardness – point to their main application area as shafts and fasteners for motors, pumps and valves in the food and process industries.

Zero carbon footprint

stainless integral to design

A dam upgrade project in South Australia has achieved a world-first zero carbon footprint for water infrastructure and has used stainless steel as part of the unique design. The Little Para Dam upgrade incorporates a Hydroplus Fusegate System, with stainless steel fabrication carried out by ASSDA Accredited Fabricator LWA Engineering.

Hydrostatic Testing of Stainless Steels

Guidelines to Ensure Long Service Life

Design engineers frequently specify stainless steel in industrial piping systems and tanks for its excellent corrosion resistance. While stainless steel’s unique characteristics make it a standout leader in the durability stakes of alloys, it is not completely immune to corrosion.