The greatest challenge we face is the control of our own success. With 7 billion people on earth, all with an insatiable appetite for a high standard of living, the newest dimension of materials competition is sustainability.

Sustainability is development that meets the needs of the present without compromising the ability of future generations to meet their own needs (UN World Commission on Environment and Development, 1987). In real terms, that means making choices that do minimum damage to our environment, but support a high level of human development.

The built environment is an excellent place to start. Buildings last for a long time, locking up the energy used in making their materials, requiring maintenance and consuming the energy used for heating and air-conditioning. They consume a large proportion of our resources. The choice of materials affects all 3 aspects of consumption, and, a number of building evaluation systems have been created around the world to assist in rating buildings for sustainability. Materials are scored for their energy content reuse during major refurbishment, waste management, recycled content and contribution to the overall design and running costs.

The Green Building Council of Australia rates green buildings for sustainability. The pace of registration and certification is increasing. Of the 368 certified projects, 96 were certified in the last 12 months. The push towards sustainable development in the building sector is strong and accelerating. City of Melbourne’s Council House 2 (CH2) is Australia’s first Green Star rated building to be awarded 6 Stars, which carries an international leadership status. Stainless steel was used to support screening walls of living green plants that shade the building and, required no maintenance or painting, working with the environment to keep good working conditions. Such membranes, containing plants or actively or passively screening the sun, allow the use of a smaller capacity air-conditioning plant, with lower capital costs and ongoing running costs and energy demand.

which carries an international leadership status. Stainless steel was used to support screening walls of living green plants that shade the building and, required no maintenance or painting, working with the environment to keep good working conditions. Such membranes, containing plants or actively or passively screening the sun, allow the use of a smaller capacity air-conditioning plant, with lower capital costs and ongoing running costs and energy demand.

The only Gold LEED® (Leadership in Energy and Environmental Design) certified meeting venue in the world is the Pittsburgh Convention Centre in the United States. Its grade 316 stainless steel roof is used to harvest rainwater, reducing water demand on the city system - another example of the special properties of stainless steel.

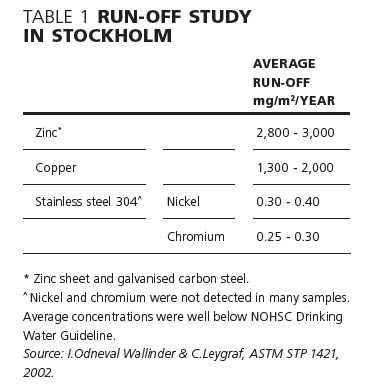

Stainless steel roofing and rainwater goods give extremely low levels of run-off. See Table 1. But this is not the only reason to use stainless steel in the built environment. It contributes to sustainability because of its long service life, excellent corrosion resistance, clean and unchanging appearance and its exceptional hygiene characteristics. Stainless steel is reusable, entirely recyclable, and probably the most recycled product in the world. On top of that, it needs very little cleaning or short or long term maintenance, and makes no contribution to indoor pollution as materials emitting volatile organic compounds (VOCs) do.

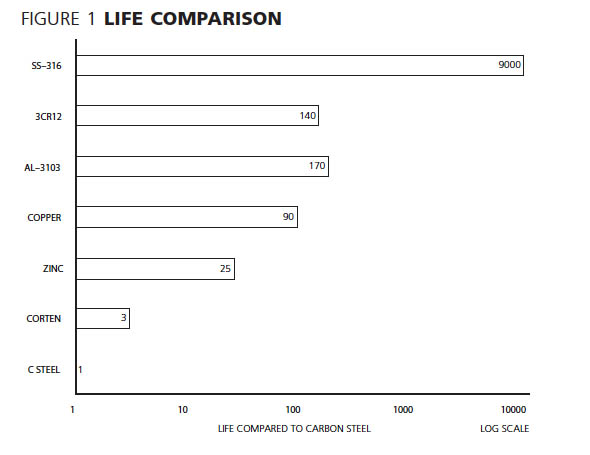

There is considerable history and experience of stainless steel service life in the built environment. The Chrysler Building (1930) and Empire State Building (1931) in New York demonstrate the material’s durability, excellent appearance and resistance to corrosion. This extraordinary functionality has been played out many times with a number of examples here in Australia, including the Fujitsu Building in Brisbane, which is clad with 445M2 ferritic stainless steel. Located in a marine industrial environment, this building looks as good as it did on completion in 2002. The long life of stainless steel in these atmospheric applications shows its very high corrosion resistance. The corrosion rate of grade 316 for instance in most atmospheres is is more than 5000 times slower than the rate of carbon steel. See Figure 1 (below).

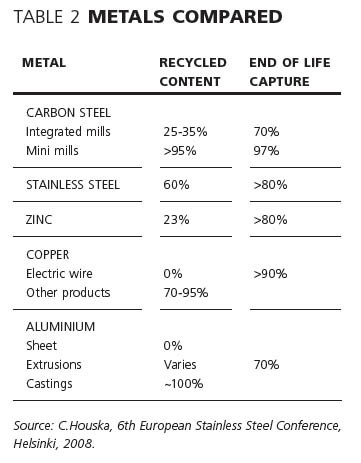

There is a considerable industry devoted to the collection and recycling of stainless steel products at the end of their life and, scrap is the standard feedstock for making stainless steel. In any stainless steel object, there is an average of 60% recycled content. New production would virtually all be made from recycled stainless steel if it were available, but the growth in the use of stainless steel and its long life in service limit the supply. Table 2 compares the recycled content and end of life capture rate of the industrial metals, and demonstrates that stainless steel is the most recycled industrial metal.

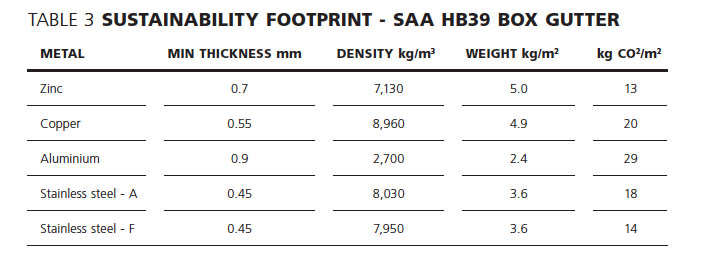

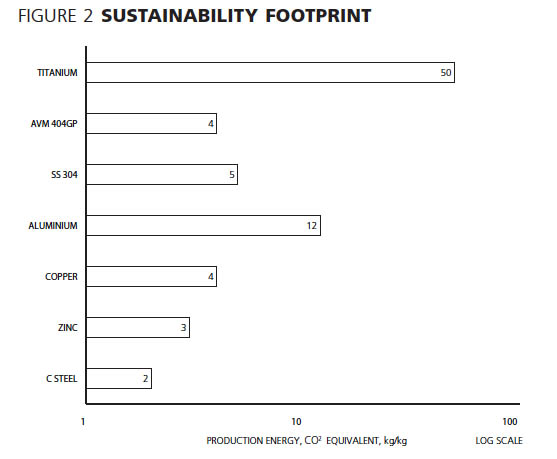

Sustainability is about much more than recycling. The energy used to make the material has a direct impact on sustainability, and all metals are energy intensive. Energy is a scarce resource, generates greenhouse gases and creates specific demands on land use likely to impact on future generations. Longevity and extraordinary recyclability will not be helpful if stainless steels’ energy consumption is much higher than other materials. Figure 2 describes the embodied energy in terms of CO2 equivalent for some of the industrial metals, and shows that stainless has a comparatively high level of embodied energy. In kilogram of CO2 per kilogram of metal, the austenitic grades are over double the footprint of carbon steel, although the ferritic grades are a little less. The footprint of stainless steel is caused by the production of alloying elements nickel and chromium, which are needed to give stainless steel its special properties, including extremely long life. Even so, efforts are ongoing in the stainless steel industry to reduce the energy content.

But in the real world, kilogram CO2 per kilogram metal comparisons are misleading. Take a typical application; a box gutter on a building. The metals have different strength, so are used with different thickness. Stainless steel gives a relatively light weight gutter (see Table 3), and hence the lowest footprint as installed. Coupled with its extended durability without maintenance, stainless comes out as the most sustainable option. Painted galvanised or Zincalume® coated carbon steel has not been included in the table as the calculation of the contributions of the components were too complex, but these materials are highly unlikely to beat the sustainability of stainless steel, even as-installed, and they have a much shorter life.

In summary, stainless steel has excellent recyclability, energy content as-installed (at least as good as other metals), extraordinary longevity and next to no need for maintenance, ever. Add to that the benefits of their special properties, which allow for the construction and operation of buildings at a lower cost. The contribution of stainless steel to sustainability is obvious and considerable.

This article was prepared by ASSDA Technical Committee member, Alex Gouch from Austral Wright Metals.

This technical article is featured in Australian Stainless magazine - Issue 50, Summer 2011/12.