Principles of Mig Welding

According to the AWS Welding Handbook volume 2, MIG welding is "an arc welding process that uses an arc between a continuous filler metal electrode and the weld pool. The process is used with shielding from an externally supplied gas and without the application of pressure". The wire is usually supplied in spools and fed through to the welding arc by an electric feed motor, with no manual control ofthe wire feeding process ie semiautomatic.

Most materials, except aluminium, use what is termed a ‘constant potential power source’, and this automatically regulates the arc gap by varying the burn off rate of the wire.

MODES OF METAL TRANSFER

There are four modes of metal transfer possible with the standard MIG welding system: short circuiting (or dip), globular, spray and pulsed modes.

Short circuiting transfer is the mode which uses the lowest amperage range, hence the lowest heat input of the four variants. Essentially the electrode contacts the molten weld pool, completing the electrical circuit. Resistance heating of the electrode takes place until the tip of the wire is melted off and transferred to the weld pool. The arc is then extinguished, until the tip of the wire comes back into contact with the weld pool, and the cycle begins again. This process is repeated between 20 to 200 per second.

Globular transfer uses slightly higher currents than for short circuit transfer, but lower than those used for the spray mode. The arc is continuous, but the molten metal is transferred across the arc in a characteristic globular fashion, with the globule diameter greater than that of the electrode.

Spray transfer uses the highest current ranges, having a continuous arc, and the weld metal transferred across the arc in many tiny droplets. The droplet diameter is equal to or less than the electrode diameter, and is also accompanied by an electric force propelling these droplets across the arc, hence the term spray transfer.

Pulsed transfer is achieved by using a lower welding current at which conventional spray transfer would not be possible, and then imposing background pulses of power through the system. Typical pulsing frequencies can be up to 40 kilohertz and this in turn transfers one droplet across the arc per pulse, thus achieving spray transfer at lower welding currents.

SHIELDING GASES

A variety of shielding gases are available from many suppliers, which have been refined to suit various applications. A major effect that these gases have, is their ability to influence arc stability and mode of metal transfer.

The common MIG shielding gases are Argon and CO2. At all usable welding currents, CO2 will commonly produce a drip or globular transfer, whilst the full range of transfers can be obtained with Argon.

Mixtures of these two gases as well as a one or two percent addition of oxygen are also common when MIG welding the carbon and low alloy

steels. They have been designed to get the best characteristics of both gases, and improve arc stability, metal flow, sidewall fusion, wetability

etc.

PROBLEMS ASSOCIATED WITH MIG WELDING SHEET MATERIALS

It should not come as any surprise that welding sheet metals by the MIG process must have limits, especially on the thinner sections. MIG welding is a relatively high heat input process, and hence the rate of heat transfer away from the weld pool becomes important. The surrounding material must be able to support and maintain the weld pool until it solidifies. The final weld must also have an acceptable bead profile, with visual and surface quality within the specification requirements. Heat input must be kept to a minimum, and this in turn implies a

short circuit or globular transfer mode. Unfortunately, these modes are prone to spatter.

A compromise must be reached between heat input, travel speed, weldability and bead shape, which are all influenced by specific gas compositions.

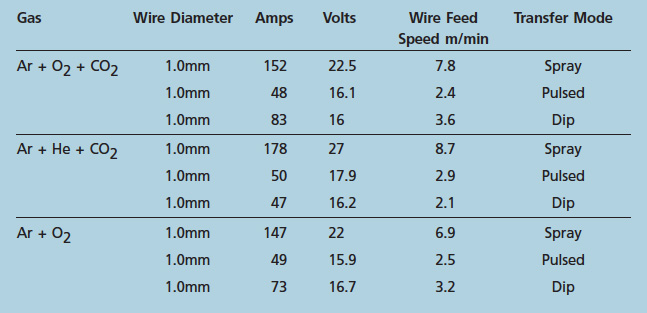

The table shows some results of MIG welding austenitic stainless steel sheet using a one millimetre diameter wire, with a variety of gases. The volts and amps recorded indicate the lowest settings which achieved the stable transfer mode indicated.

The values of interest, and which formed the basis for the experiment, are the electrical settings, namely the amps and volts. Travel speed is obviously important in reducing heat input, but the effect of gas composition on the stable mode of transfer was the primary objective.

CONCLUSIONS

The results obtained not only confirmed the expected problems when welding thin stainless sheet, but also produced some interesting points

when using the pulsed transfer mode. As expected, spray transfer is not recommended for thin sheet.

Helium, as an alternative addition to shielding gases definitely has advantages in achieving an acceptable weld profile over the more common

gas mixtures, even in semi-automatic welding, but a greater degree of competency is required by the welder to be able to handle the necessary faster travel speeds.

Pulsing helps to overcome the problems associated with bead shape and burn-through, and if the equipment is available, it negates the advantages offered by a helium containing gas. Higher travel speeds in the pulsed mode are still necessary with the helium addition. The use of a helium-containing mixture with the pulsed mode should offer a combined benefit of a lower heat input and faster production rates, and, hopefully, less distortion as a result.

Words by Jim Henderson.

Reproduced with permission from the Australasian Welding Journal Volume 45 Fourth Quarter page 21.

This article featured in Australian Stainless magazine - Issue 20, February 2002.