Innovation Design Set to Transform the Industry

For the past six decades, the welding process has only been tweaked and modified, but one Adelaide company has developed a new process set to save millions of dollars and forever change the way welds are performed.

DEVELOPMENT

In 2000, Dr Laurie Jarvis and his associates at CSIRO Adelaide studied the effect of surface tension within an active weld. It was noted that under certain conditions, namely narrow gaps and increased process conditions, that far greater speeds could be obtained when welding clean materials.

The team developed a brand new process involving a high speed, single pass, full penetration welding technology that significantly reduces the need for wire or edge bevelling and is not required where autogenous welds are acceptable.

The result is a flawless finish at a speed up to 100 times faster than TIG welding in materials up to 16mm in thickness.

By definition, clean materials include stainless steels, nickel alloys, titanium and zirconium. Other materials with high impurities (such as alloy steels) cause the weld arc to become unstable and the process becomes unmanageable.

NEXT STEP

With Dr Jarvis as technical leader, a group of experienced materials experts formed K-TIG. Today K-TIG has progressed into many world markets with the system, winning a number of awards along the way.

The K-TIG process involves a specially controlled high current arc which opens a full penetration keyhole in the joint between the two welding surfaces.

Featuring extremely high stability and operating over a wide range of welding currents, K-TIG looks set to become the next big thing in fabrication.

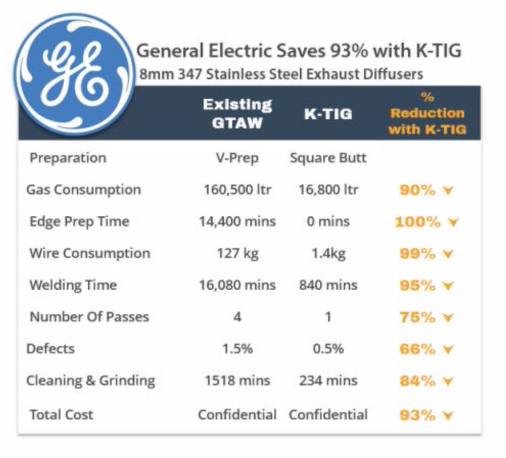

Since its inception, K-TIG has achieved enormous growth in the market, with the technology being exported to eighteen countries. Customers using stainless steels are typiclaly saving 90% on production costs.

THE PROCESS

The process ideally suits non-corrosive and exotic materials with a thickness range of 3mm to 16mm for single pass welding, however thicker metals can be welded by multiple passes.

K-TIG easily handles the traditionally difficult material, super duplex.

As for energy consumption, K-TIG consumes as little as 5% of the energy and gas consumed by TIG/GTAW for the same weld, dramatically reducing its carbon footprint.

A typical K-TIG weld is performed in a fraction of the time of a conventional weld, in a single full-penetration pass using just one welding gas.

The resulting weld is with multiple fusion lines, dramatically reducing the potential for inclusions, porosity and other defects typical of many welding processes.

The K-TIG system can monitor and control the addition of wire to a weld if that is desirable.

This article in Australian Stainless Magazine Issue 59 (Winter 2017).