Guidelines to Ensure Long Service Life

Design engineers frequently specify stainless steel in industrial piping systems and tanks for its excellent corrosion resistance. While stainless steel’s unique characteristics make it a standout leader in the durability stakes of alloys, it is not completely immune to corrosion.

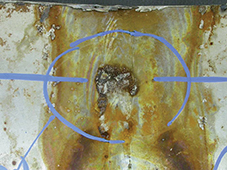

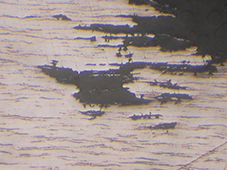

Premature failures of the stainless steel can occur due to Microbiologically Influenced Corrosion (MIC). This corrosion phenomenon usually occurs when raw water used for hydrostatic pressure tests is not fully removed from the pipework and there is an extended period before commissioning of the equipment. The result is localised pitting corrosion attack from microbacterial deposits that, in severe cases, can cause failure within a few weeks. MIC is easily prevented using proper hydrostatic testing techniques.

MIC

MIC failures occur by pitting corrosion, often at welds, where colonies of bacteria may form. A number of different bacterial species are known to cause the problem, but the detailed mechanism is not known.

Iron utilising bacteria appear to be the dominating microbial species involved with MIC occurring in stainless steel. Anaerobic sulphate-reducing bacteria pose a greater risk of instigating or accelerating corrosion often under a layer of aerobic slime or microbial deposits. However others, such as manganese utilising bacteria (generally from underground waters), have also been discovered.

MIC is extremely aggressive and difficult to eliminate once established, so it is surprising and disappointing that there is limited knowledge of MIC within the engineering community. Fortunately, MIC is easily avoided by using good practices during the initial hydrostatic testing. Education and promotion of proven hydrostatic testing practices which prevent MIC are vital to minimising its potential impact on the stainless steel industry.

Hydrostatic testing practices to eliminate MIC

In order to eliminate MIC, it is recommended that the following practices are used.

1. Fabrication practices

Crevices should be eliminated or at least minimised during the fabrication process, as they are the preferred sites for attachment and growth of microbial colonies. They also provide traps for chemicals which could concentrate and cause pits.

The likelihood of MIC will also be reduced by:

- Using full penetration welds; and

- Purge welding to prevent the formation of heat tint; or

- Removing heat tint by grinding or pickling.

Arc strikes and weld splatter should also be ground off and pickled.

2. Use clean water

The cleanest water available should be used in a hydrostatic test, such as demineralised, steam condensate or treated potable water. Untreated or raw water from dams or bores should be avoided when conducting a hydrostatic test but, where this is not possible, the water should be sterilised (e.g. by chlorination) before use. If sterilisation is not practical, the requirements for short residence time and subsequent drying of the system are extremely important. The cleaner the water, the less ‘food’ there is for MIC bacteria to live off and multiply.

It is important to ensure that there is no trace of sediment in the stainless steel system during testing to avoid silting, as the water is normally not circulated during a hydrostatic test. This may require the test water to be filtered to ensure it is free of all undissolved solids. Sediments can provide the conditions for crevice attack.

3. Draining and drying

Thoroughly draining and drying the stainless steel system immediately following a hydrostatic test (preferably within 24 hours, certainly within 5 days) will almost certainly prevent the occurrence of MIC.

Horizontal pipelines should be installed in a sloping direction to make them self-draining.

Drying can be achieved by pigging (cleaning with foam or rubber scrapers), followed by blowing dry air through the system. Beware of blowing higher temperature moist air through cold pipework unless the air is dried before being introduced to the system. If warm air is used, it should not be from a gas burner as condensation may occur.

Draining and drying of systems following a hydrostatic test should only be disregarded when the system is placed into service immediately following the test. Partial draining is potentially very serious as subsequent slow evaporation of even clean residual water can produce very concentrated and aggressive solutions.

4. Chloride content and temperature

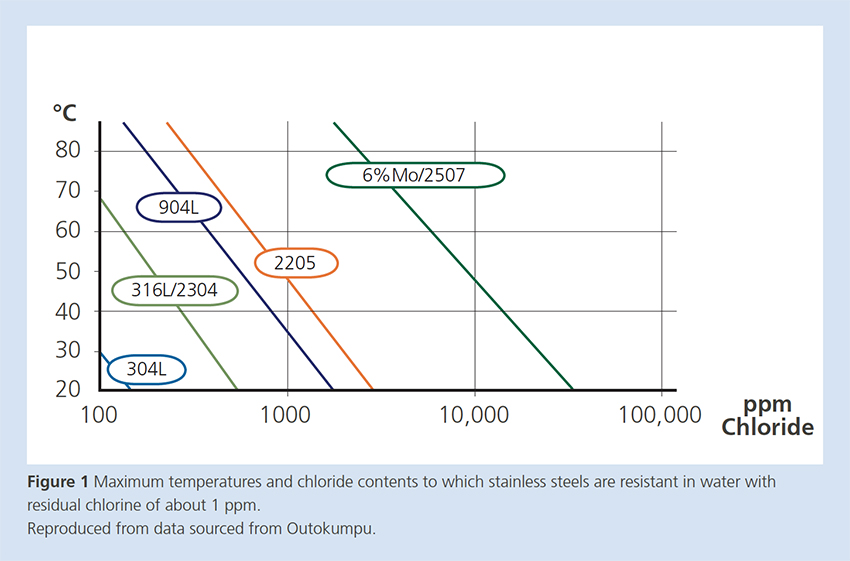

During hydrostatic testing of stainless steel equipment, the chloride content of the test water must be within the range to which the stainless steel grade is resistant. Figure 1 shows the maximum temperatures and chloride contents to which stainless steels are resistant in water with residual chlorine of about 1 ppm.

The limits shown in Figure 1 may be exceeded provided the contact time of the water is brief, i.e. 24-48 hours.

If the chloride content of the test water is uncertain, the water should be analysed.

5. Standards

NACE and API standards for a number of products and installations provide guidelines for hydrostatic testing, including limits for water quality and contact times. These standards should be consulted for specific details for the fabrication in hand.

Conclusion

The benefits of stainless steel’s corrosion resistance are well proven in many industrial applications involving piping systems, but failures can occur during hydrostatic testing if care is not taken. Attention to a few simple details will prevent surprises a few months down the track, allowing the long service life available from stainless steel to be fully realised.

This article featured in Australian Stainless Issue 47 - Spring 2010.