This is an abridged version of a story that first appeared under the same title in Stainless Steel Focus No. 07/2012.

The Nickel Institute's director of promotion, Peter Cutler, and consultant Gary Coates, reveal some of the reasons for the continuing popularity of nickel in stainless steels.

Stainless steel is everywhere in our world and contributes to all aspects of our lives. We find stainless steel in our homes, in our buildings and offices, in the vehicles we travel in and in every imaginable industrial sector. Yet the first patents for stainless steel were issued only 100 years ago.

How

ject was commissioned by the Gold Coast City Council (GCCC) to redevelop the beachfront area between Laycock Street and View Avenue in Surfers Paradise.

ject was commissioned by the Gold Coast City Council (GCCC) to redevelop the beachfront area between Laycock Street and View Avenue in Surfers Paradise.

Covering 103,000m2, the $1.2 billion Westfield Sydney development is bound by the Pitt Street Mall and Market and Castlereagh Streets in the heart of Sydney’s CBD. It integrates Westfield Centrepoint, the Centrepoint Convention Centre, Imperial Arcade and Skygarden, plus a new office tower at 85 Castlereagh Street and an extensively modified and refurbished tower at 100 Market Street.

Covering 103,000m2, the $1.2 billion Westfield Sydney development is bound by the Pitt Street Mall and Market and Castlereagh Streets in the heart of Sydney’s CBD. It integrates Westfield Centrepoint, the Centrepoint Convention Centre, Imperial Arcade and Skygarden, plus a new office tower at 85 Castlereagh Street and an extensively modified and refurbished tower at 100 Market Street.

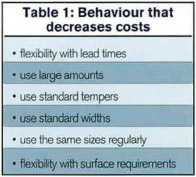

Australia is a relatively 'small fish' in the global stainless industry and, without the benefit of local stainless steel production, loses some flexibility on product availability. Unless you're a very large consumer of stainless steel to a single specification or Standard, ordering to common specifications will reduce costs and increase availability of products.

Australia is a relatively 'small fish' in the global stainless industry and, without the benefit of local stainless steel production, loses some flexibility on product availability. Unless you're a very large consumer of stainless steel to a single specification or Standard, ordering to common specifications will reduce costs and increase availability of products. Suppliers are likely to have products to common specifications. Ordering them reduces the

Suppliers are likely to have products to common specifications. Ordering them reduces the

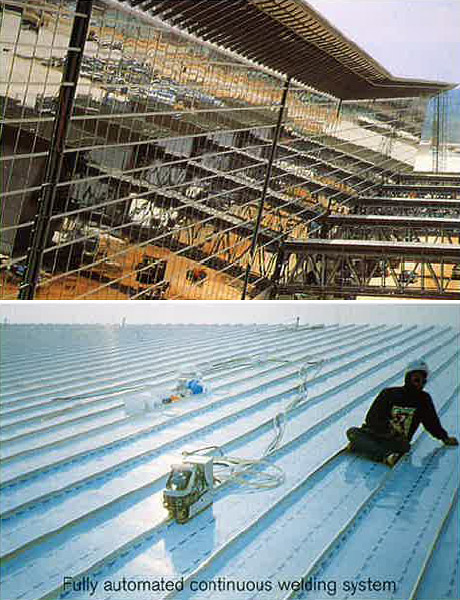

The roof profile of the contact piers and air bridges (60,000m2 total area) had to satisfy a number of criteria, including rainwater runoff, resistance to wind uplift, and a smooth, painted appearance. The roof area comprises a composite system with an outer metal membrane of fully-welded stainless steel. Further complicating the design, the architect (MJAC) wanted to avoid valley gutters on the roof's curves.

The roof profile of the contact piers and air bridges (60,000m2 total area) had to satisfy a number of criteria, including rainwater runoff, resistance to wind uplift, and a smooth, painted appearance. The roof area comprises a composite system with an outer metal membrane of fully-welded stainless steel. Further complicating the design, the architect (MJAC) wanted to avoid valley gutters on the roof's curves.

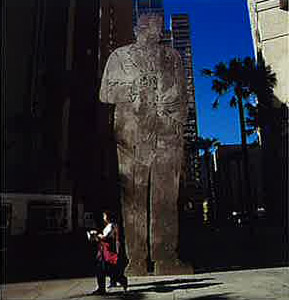

Sydney artist Simeon Nelson designed 'Ben Chifley' and a glass and stainless steel wall on the site while working as part of the multi-disciplinary design team involved in the site's $3 million redevelopment. Hassell architects (Sydney) were given open guidelines for the design of the site, but two of the objectives

Sydney artist Simeon Nelson designed 'Ben Chifley' and a glass and stainless steel wall on the site while working as part of the multi-disciplinary design team involved in the site's $3 million redevelopment. Hassell architects (Sydney) were given open guidelines for the design of the site, but two of the objectives

170 metres of tube was used for the staircase, which was spiralled and fixed to the mild steel structure of the building. Washers and neoprene gaskets were used to separate the stainless steel from the mild steel, avoiding corrosion issues caused by dissimilar metal contact.

170 metres of tube was used for the staircase, which was spiralled and fixed to the mild steel structure of the building. Washers and neoprene gaskets were used to separate the stainless steel from the mild steel, avoiding corrosion issues caused by dissimilar metal contact.

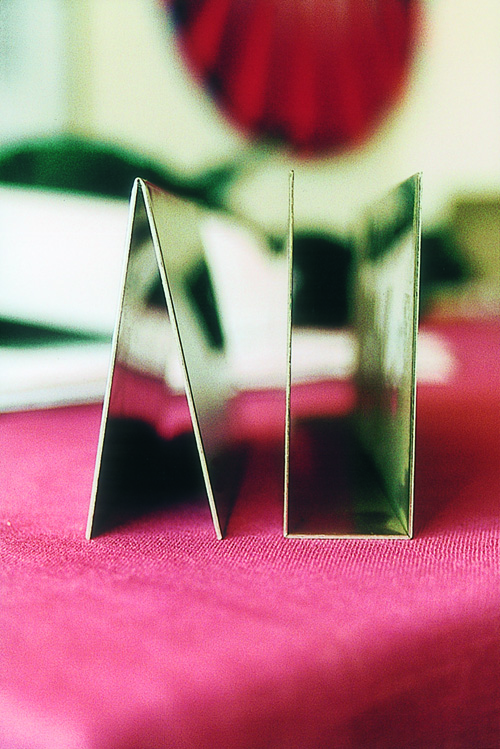

Thanks to vee-cut technology, stainless steel sheet can be formed into angles as precise as those obtained by extrusion. This technology is now being carried out in Sydney, allowing the local manufacture of a whole range of stainless steel architectural products. The technique is particularly suited to elements such as door fronts, window frames, shopfronts, showcases, elevator doors as well as all forms of cladding.

Thanks to vee-cut technology, stainless steel sheet can be formed into angles as precise as those obtained by extrusion. This technology is now being carried out in Sydney, allowing the local manufacture of a whole range of stainless steel architectural products. The technique is particularly suited to elements such as door fronts, window frames, shopfronts, showcases, elevator doors as well as all forms of cladding.

According to the Site Co-ordinator Keith Vanderstaay, the caves "have been reinvented with the completion of a state of the art, computer-controlled lighting system which will change the way everybody will see the cave."

According to the Site Co-ordinator Keith Vanderstaay, the caves "have been reinvented with the completion of a state of the art, computer-controlled lighting system which will change the way everybody will see the cave."

Manufacturing by an Australian firm will also make it easier for specificiers to communicate their special requirements.

Manufacturing by an Australian firm will also make it easier for specificiers to communicate their special requirements.

While the former Premier's impact on the Victorian capital has been comprehensive, the refurbishment of Brighton Sea Baths as an upscale nightspot part-owned by Mr Newman has contributed a smaller scale landmark which is just as likely to provide visitors (male ones, anyway) with a memorable impression of the city.

While the former Premier's impact on the Victorian capital has been comprehensive, the refurbishment of Brighton Sea Baths as an upscale nightspot part-owned by Mr Newman has contributed a smaller scale landmark which is just as likely to provide visitors (male ones, anyway) with a memorable impression of the city.

The originality of the design complements the creative nature of the activities housed in the building, situated on the edge of Adelaide’s Light Square.

The originality of the design complements the creative nature of the activities housed in the building, situated on the edge of Adelaide’s Light Square.