Posted 1 July 2003

John Hodgkinson is mad about hams! The managing director of ASSDA member Smo-King Ovens really loves his products and is passionate about helping butchers generate more business through their use.

Posted 1 July 2003

John Hodgkinson is mad about hams! The managing director of ASSDA member Smo-King Ovens really loves his products and is passionate about helping butchers generate more business through their use.

A decor has to be unique to stand out among the trendy cafes and nightclubs in Park Road, Milton, one of Brisbane’s most fashionable locations, and it certainly has to possess the wow factor to compete with the multitude of sensory experiences which greet clubbers out to see the latest bands and DJs.

Posted 1 July 2003

Consumers expect processed foods to be tasty and nutritious, affordable and safe. To meet these expectations, food contact equipment has to be hygienic and productive.

Lightweight stainless steel construction has allowed the proprietor of a Tasmanian cafe to expand operations without building new brick and mortar premises.

Our three-part series on coated abrasives concludes with information on choosing the correct abrasive product for the desired finish. Read Part 1. Read Part 2.

To symbolise the wetlands landscape of the Nundah area in Brisbane’s north, sculptor Daniel Della Bosca sought out materials which best convey the fluidity and reflectivity of water and the reedy texture of waterside vegetation.

Posted 1 July 2003

Stainless steel combines structural strength with corrosion resistance to form a superior construction material which additionally supports a range of aesthetically pleasing finishes.

Posted 1 July 2003

Architect Jan Jensen was a consultant to Brisbane City Council on the design of the Brisbane Riverwalk, currently under construction. The walk will take pedestrians from the CBD to the inner suburb of New Farm along the river.

Posted 1 July 2003

The long-term cost effectiveness of stainless steel makes it a worthwhile proposition even though the initial outlay can be significant. The construction industry is realising that choosing a cheaper, but less durable material can be a false economy.

When Canberra-based Artist, Anna Eggert began sculpting with stainless steel wire mesh two years ago she tried every tool to model the material with little success.

Coastal areas are popular sites for recreational fun and fantastic fishing. However, the City of Albany in Western Australia had one major problem to deal with - fish waste in the nearby waterways

Posted 30 November 2003

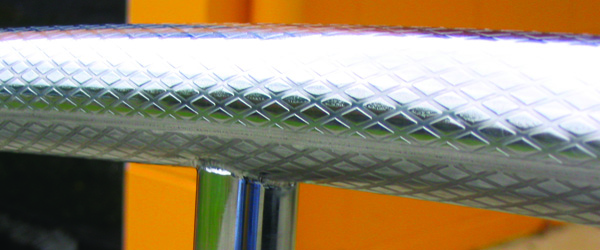

The humble stainless steel rail is set to become a visual feature with the introduction of an innovative new product that people just can't keep their hands off.

Successfully using stainless steel depends on environment, grade selected, surface finish, the expectations of the customer and the maintenance specified.

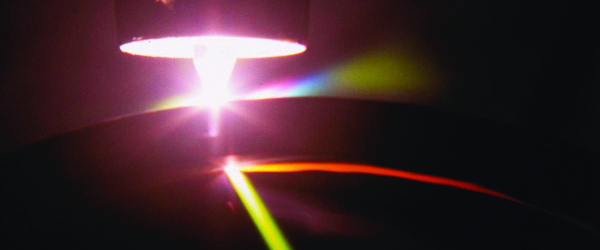

Stainless steels provide robust solutions, but in harsh or borderline environments with high expectations for durability, surface finish will have a substantial impact on performance. Surface finishes can be applied mechanically (usually with abrasives) and chemically.

Understanding how chemical and mechanical treatments will affect the characteristics of the surface and will enable the best possible outcome for the client and the structure. Chemical treatment can be used to improve the corrosion performance of the steel, and hence its appearance in service.

PDT Architects, Brisbane in association with HOK Sport, Venue and Event designed and documented the $280m Suncorp Stadium for the Queensland Government.

"It is the top grade material and that's what we wanted for the stadium...

When you take that the client is the people of Queensland, they expect the best to go into the stadium.

If they're paying $280 million for a stadium they want the thing to last and stainless will give you that longevity."

Posted 30 November 2003

Researchers from the Commonwealth Scientific and Industrial Research Organisation (CSIRO) and the Cooperative Research Centre for Welded Structures (CRC-WS) have developed a welding process for stainless steels and other corrosion-resistant metals that is significantly faster, cheaper and easier than current practices.

Tamarama Beach or as local Sydneysiders call it 'Glamarama Beach', is well known as the place for beautiful people to be seen and for the rest of us to dream.

Brewed for Efficiency

When Carlton & United Breweries (CUB) announced plans last year to expand production capacity at the Yatala site in Queensland, the company considered both purchase of new stainless tankage as well as transfer of tanks from its Sydney brewery and re-use of second hand tanks in its inventory.

For many years there has not been a Standard to cover the low pressure stainless steel cast pipe fittings commonly used in Australia and other countries around the world.

"Windhover" is a dramatic stainless steel sculpture created by the late Lenton Parr, located on the eastern foreshore of Port Phillip Bay in Sandringham, Melbourne.

A crevice is a narrow gap between a piece of metal and another piece of metal or tightly adhering material like plastic or a film of bacterial growth.

Many metals and alloys are susceptible to crevice corrosion, but in stainless steel, crevices are the first and most common place for corrosive attack to begin. With a little understanding, crevice corrosion can either be avoided or minimised.