Advanced engineering solutions are required to handle conditions found on offshore drilling and processing platforms. The saltwater environment is highly corrosive, the flare presents extremes of temperature and the force of winds and currents is constant. The most durable and reliable materials need to be employed, which is why stainless steel plays and important part.

An impressive project making use of stainless' strength and corrosion-resistance is the Bayu Undan Gas Project in the Timor Sea, 5OOkm north of Darwin (pictured). Here, stainless steel is used to line the 18" pipelines between the processing platform and the wellhead platform 8km distant

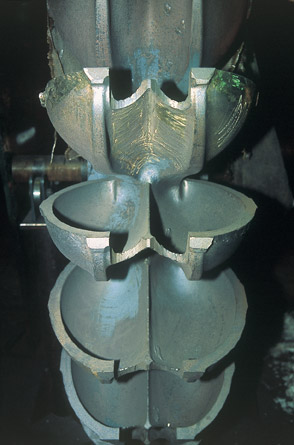

Flameproofing of material handling equipment is the science of reducing the risk of an explosion or fire by means of specialised principles and technologies.

Flameproofing of material handling equipment is the science of reducing the risk of an explosion or fire by means of specialised principles and technologies.

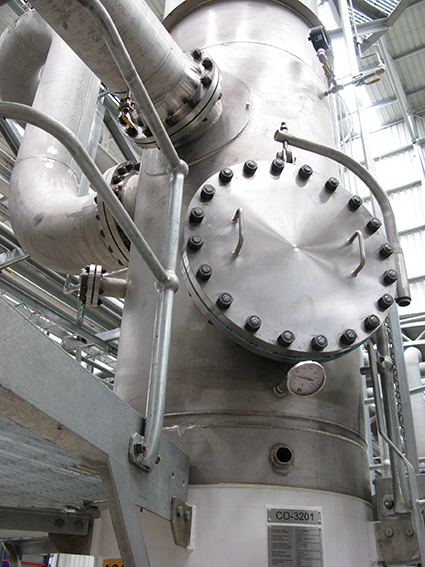

The construction of Bundamba Advanced Water Treatment Plant (BAWTP) west of Brisbane is aimed at alleviating pressure on South East Queensland’s existing dams and waterways by providing an alternate water supply for end users in the region, initially Swanbank power station.

The construction of Bundamba Advanced Water Treatment Plant (BAWTP) west of Brisbane is aimed at alleviating pressure on South East Queensland’s existing dams and waterways by providing an alternate water supply for end users in the region, initially Swanbank power station.