When used properly, stainless steel enjoys a strong and enduring reputation for visual appeal and structural integrity in a wide range of applications and environments.

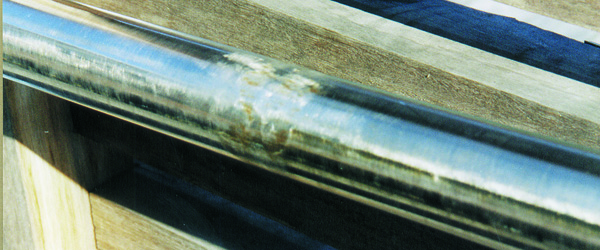

But, like all materials, stainless steel may become stained or discoloured over time, impairing the overall look. This brown discolouration - tea staining - has been identified in coastal applications in Australia and overseas.

Factors affecting tea staining have been researched by ASSDA and the information gathered has been supported by experiences from around the world.

This article provides information on tea staining and what fabricators, specifiers and end users should do to help avoid

Underpinning theory and practical training in stainless steel represents only a small part of TAFE fabrication education in Australia. Understanding of standard industry terms such as pickling and passivation, crevice corrosion and knowledge of all the stainless steel grades by students even after completion is minimal.

Underpinning theory and practical training in stainless steel represents only a small part of TAFE fabrication education in Australia. Understanding of standard industry terms such as pickling and passivation, crevice corrosion and knowledge of all the stainless steel grades by students even after completion is minimal.

Unveiled just three days from the start of the Melbourne 2006 Commonwealth Games, the 10 sculptures are a tribute to multiculturalism.

Unveiled just three days from the start of the Melbourne 2006 Commonwealth Games, the 10 sculptures are a tribute to multiculturalism.

Bridgeman's Managing Director Len Webb said there was previously no system available

Bridgeman's Managing Director Len Webb said there was previously no system available

ASSDA member Southern Stainless typically specialises in the manufacture of stainless steel products including wine storage and fermentation tanks and marine fitouts, but supplying stainless steel barbeques, boat mounting systems and accessories to the general public, wholesalers, retailers and building industry

ASSDA member Southern Stainless typically specialises in the manufacture of stainless steel products including wine storage and fermentation tanks and marine fitouts, but supplying stainless steel barbeques, boat mounting systems and accessories to the general public, wholesalers, retailers and building industry