Using AS/NZS 1554.6 effectively means rather more than requiring “Weld finishing to AS/NZS 1554.6”. The standard is an effective way to get the finish you want or need on stainless steel structures. This guide should help you to nominate the quality of weld to the standard.

What is this standard?

This standard is for welding any non-pressure stainless steel equipment and when it was first drafted in 1994, its structure followed that of Part 1 dealing with carbon steel. A major revision in 2012 removed redundant text, expanded the good workmanship guidelines and brought the weld assessment and finishing processing

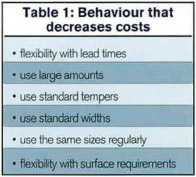

Australia is a relatively 'small fish' in the global stainless industry and, without the benefit of local stainless steel production, loses some flexibility on product availability. Unless you're a very large consumer of stainless steel to a single specification or Standard, ordering to common specifications will reduce costs and increase availability of products.

Australia is a relatively 'small fish' in the global stainless industry and, without the benefit of local stainless steel production, loses some flexibility on product availability. Unless you're a very large consumer of stainless steel to a single specification or Standard, ordering to common specifications will reduce costs and increase availability of products. Suppliers are likely to have products to common specifications. Ordering them reduces the

Suppliers are likely to have products to common specifications. Ordering them reduces the